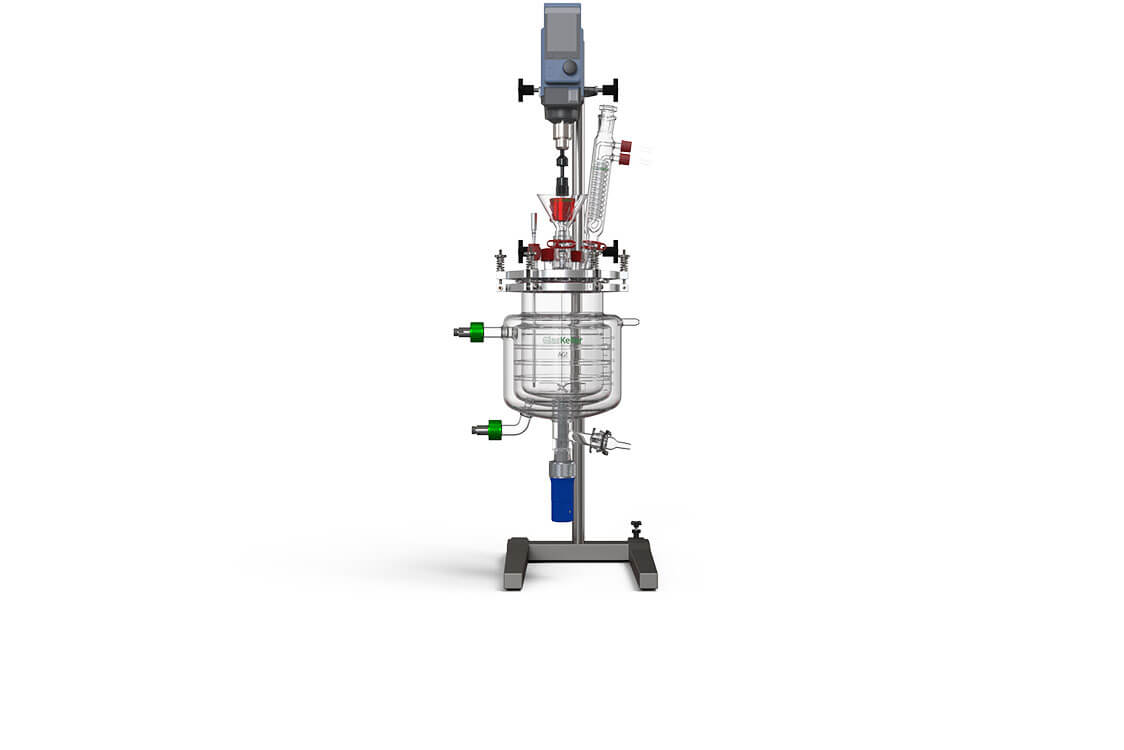

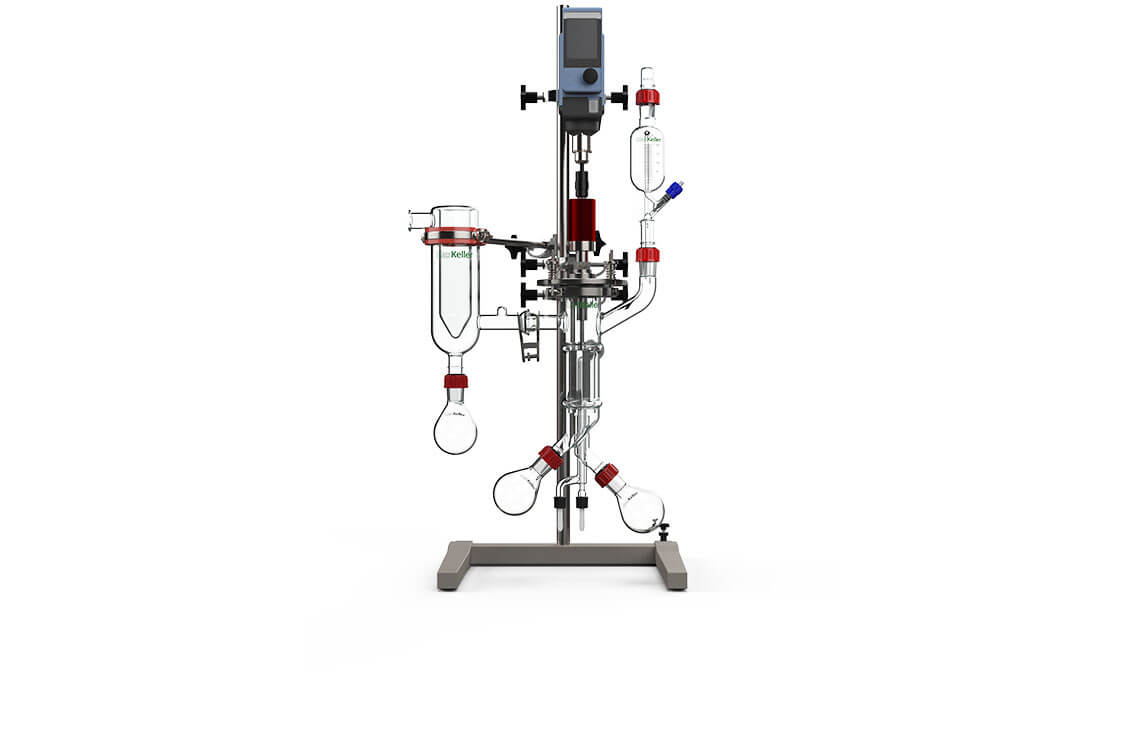

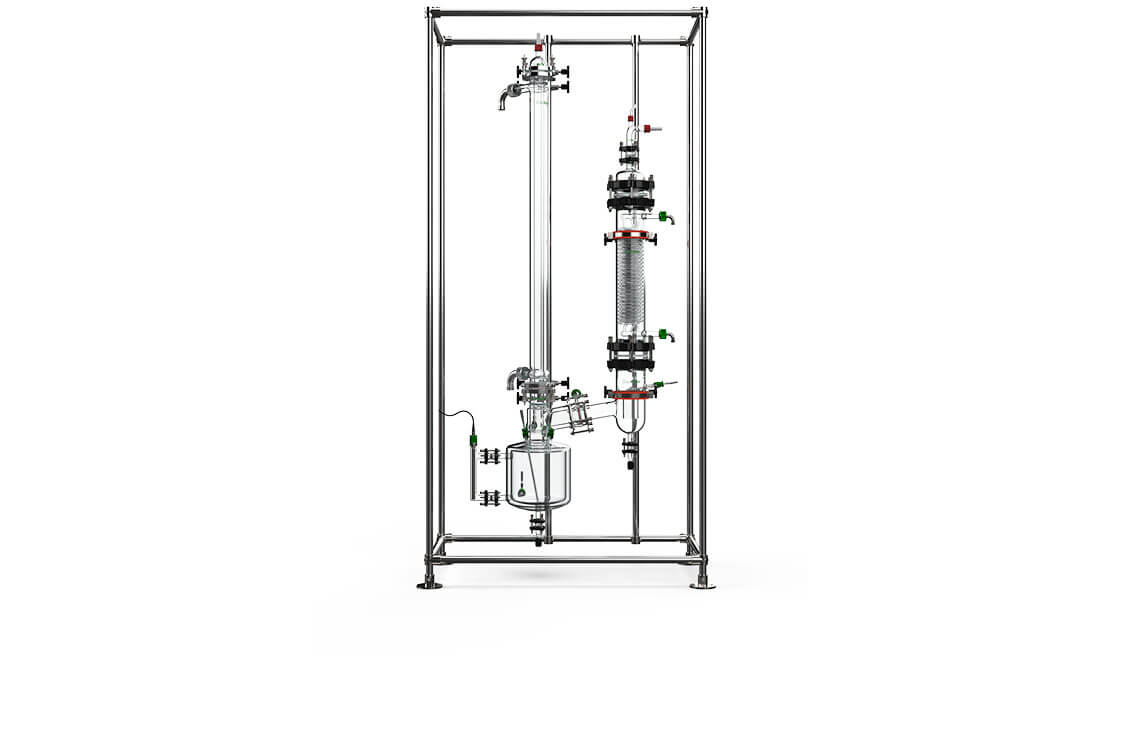

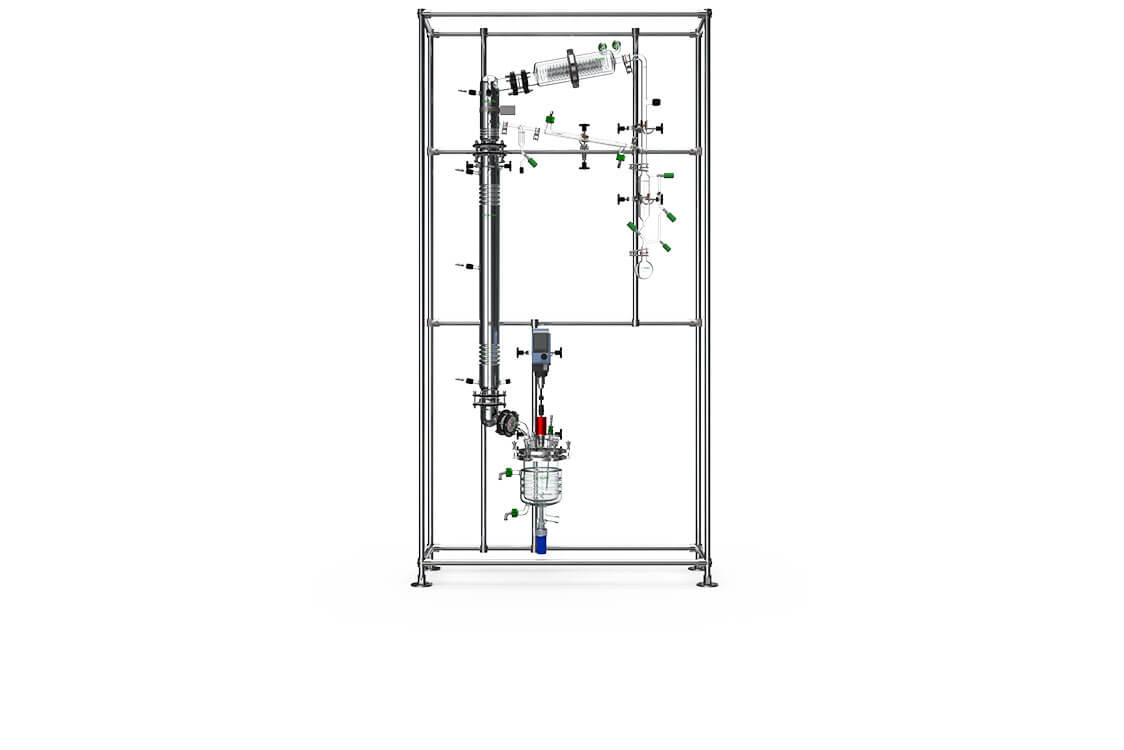

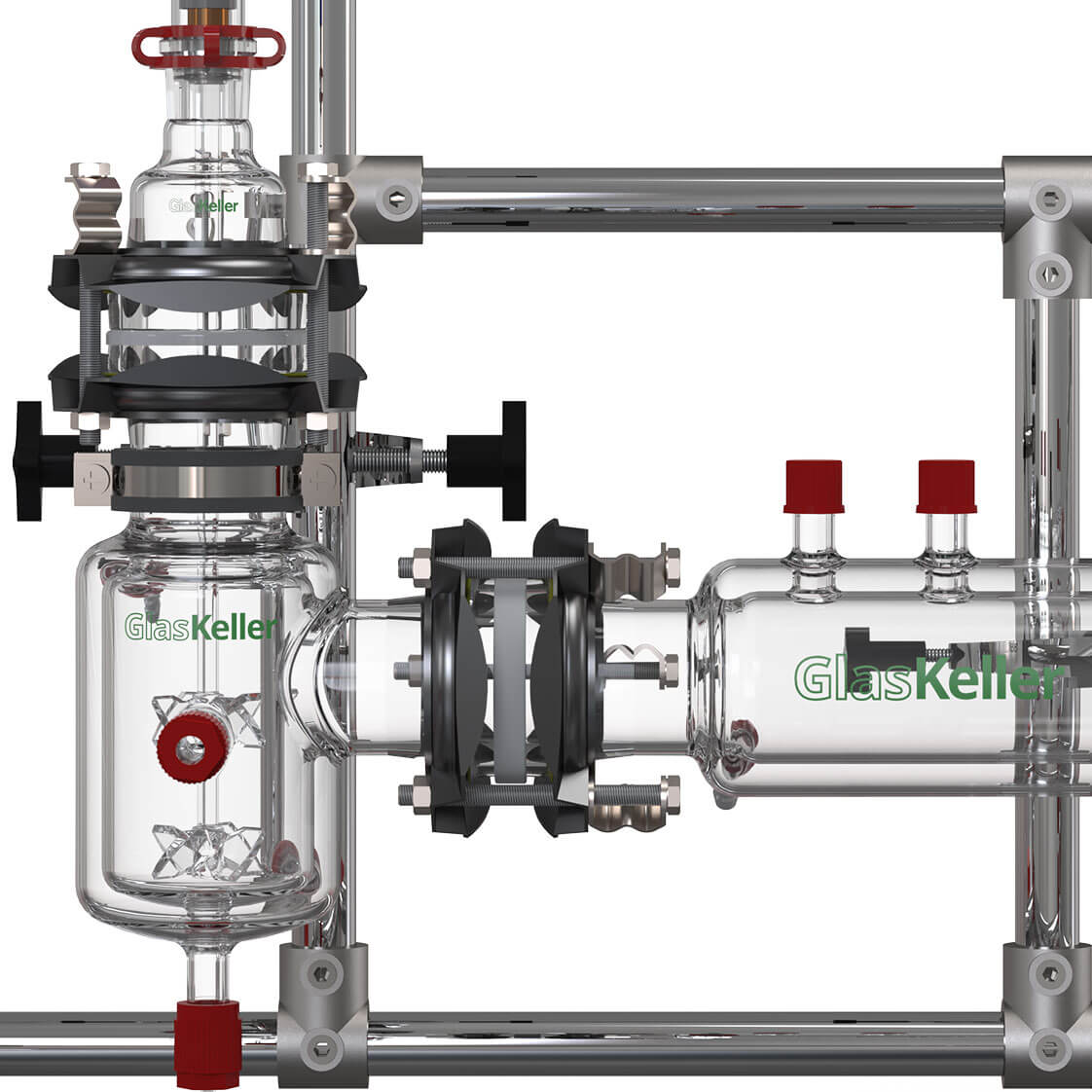

Mixer Settler

The Mixer Settler, is the standard solution for simple liquid-liquid extractions. High separation efficiency is ensured by the optimal droplet size and residence time, as well as the flexible adaptation of the geometries to different throughput and operating conditions.

Specifications

Volume*

TO BE DECIDED

Operating temperature

-20°C to +200 °C

(typical operating temperature range +20°C to +80 °C)

Vessel type

Single wall, double wall

Operating pressure

Operating pressure

Separation time

Suitable for both short extraction times (0.5 – 15 min) and long extraction times (>15 min) **

Multi-step

Systems can be used in single more or sequentially for multi-step processes**

Coating options

Breakage protection, Antistatic

Wetted materials

Borosilicate glass 3.3, PTFE (SS316L and Hastelloy options available)

*custom sizes available

**discuss your process with our in-house specialists to define correct configuration

Our Mixer-Settler simple design with low overall height enables easy scale-up.

High separation efficiency is ensured by the optimal droplet size and residence time, as well as the flexible adaptation of the geometries to different throughput and operating conditions.

In addition, the application is insensitive to suspended solids. The settler has a height-adjustable overflow for the heavy phase and can be shut down and reused without loss of time. Suitable for use in a variety of industries, including chemical, petrochemical and pharmaceutical.

MESSAGE US

We are here to help

Whether you are an existing customer looking to reproduce your glassware or someone with an entirely new challenge, we deliver unbeatable product quality and excellent support from enquiry to delivery, and beyond.

Contact us to get started.