Systems

With over 100 years of experience in precision glass manufacturing, our systems have been designed as a standard solution that can be customized to meet your requirements.

Designed for R&D departments through to Kilolab scale for applications such as separation, crystallization, evaporation, filtration and reaction.

Systems

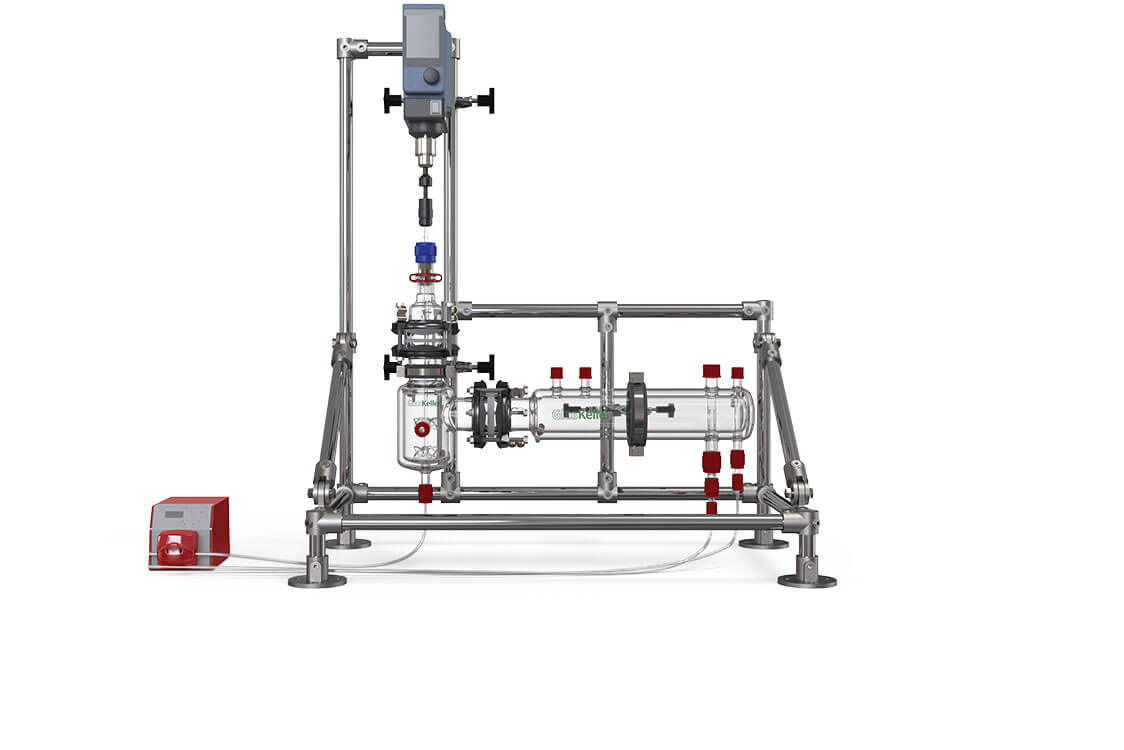

Mixer-Settler

Mixer-Settler (mixer-separators) with mixing chamber and directly attached separatpr via double weir, or an insivisual separator.

| Volume |

Mixer: 100ml – 5000ml Settler: 200ml – 10’000ml |

| Operating temperature |

-20 to +200 °C |

| Vessel type |

Single wall, double wall |

| Separation time |

0.5 – 15 Min |

| Multi-step |

single or more sequentially for multi-step processes |

| Coating options |

Breakage protection, Antistatic |

Systems

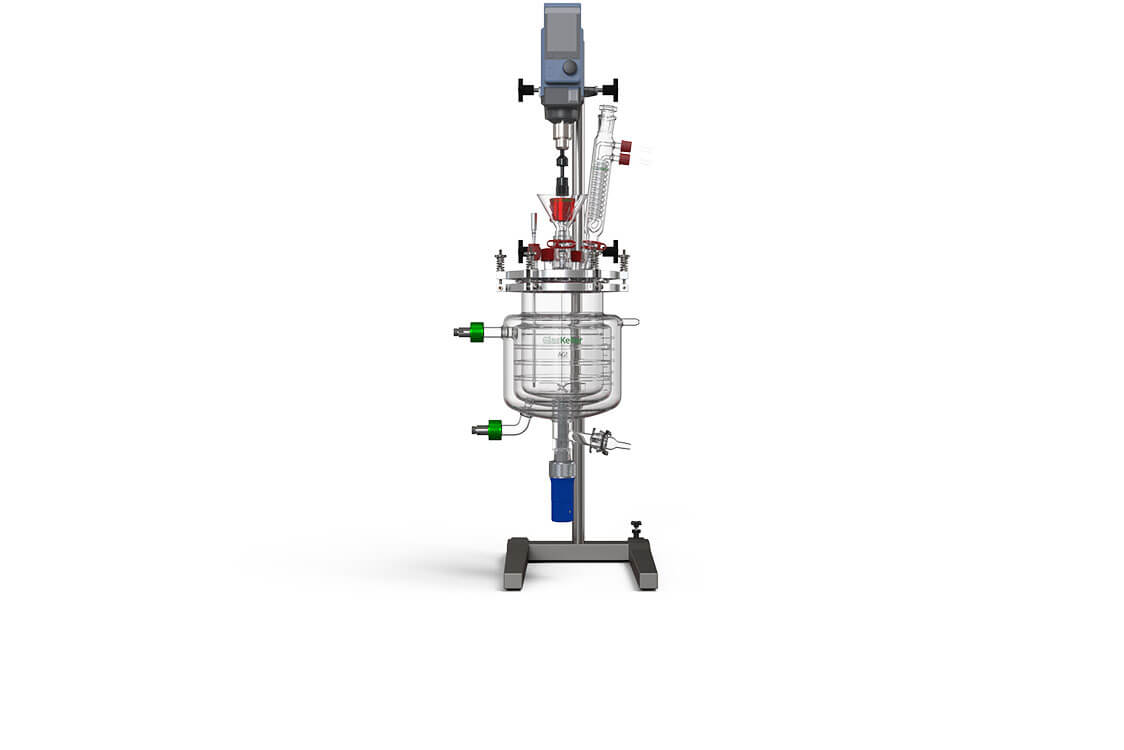

Reactor

Accurate and effective temperature control, and minimal energy loss when using our reaction vessels.

| Reactor volume | 50ml – 30L |

| Reactor diameter range | DN50 – DN300 |

| Reactor type | Single wall, double wall, triple wall, with ring baffles |

| Separation time |

short extraction times (0.5 – 15 min) long extraction times (>15 min) |

| Multi-step |

single or sequentially for multi-step processes |

| Coating options |

Breakage protection, Antistatic |

Systems

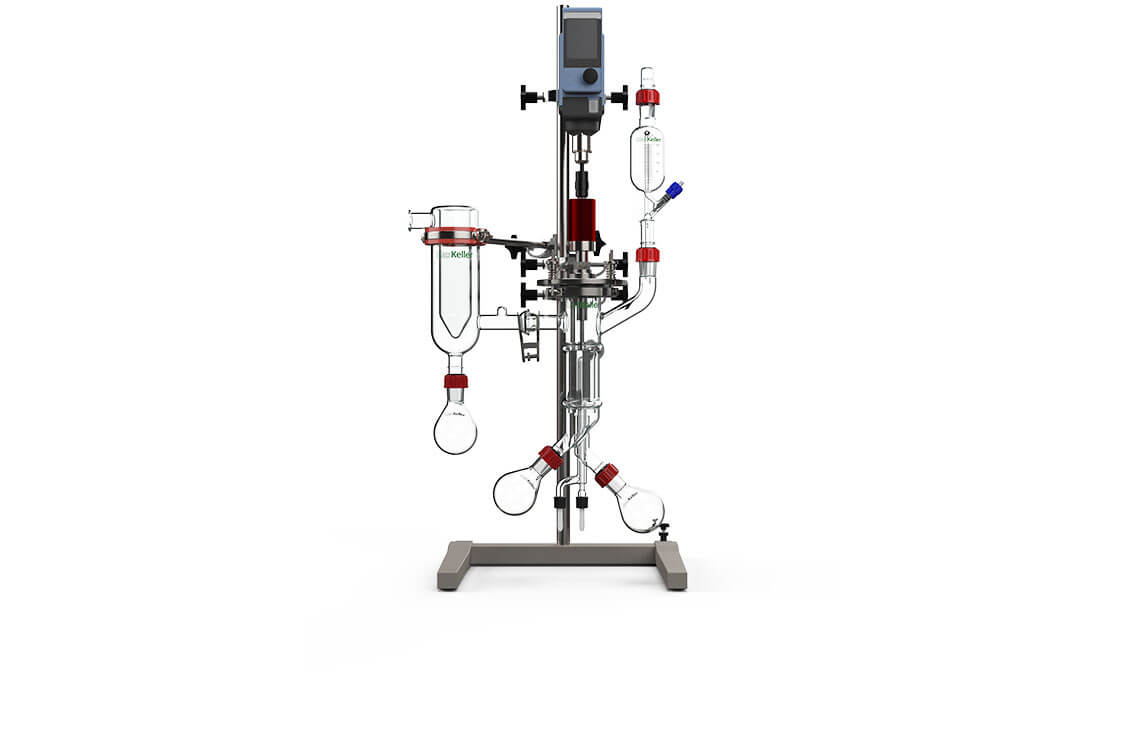

Peptide Reactor

Glass Peptide Reactor systems are advanced jacketed glass reactors meticulously engineered for precision in Solid Phase Peptide Synthesis (SPPS).

| Volume |

200ml – 30L |

| Reactor diameter range |

DN50 – DN300 |

| Reactor type |

Double wall, full jacket |

| Operating temperature |

-30°C to +200 °C |

| Filter | Filter cloth and glass sintered plate options available with a wide range of pore sizes |

| Coating options |

Breakage protection, Antistatic |

Systems

Thin Film Evaporator

The Thin Film Evaporator is designed for the efficient separation of volatile components from heat-sensitive, viscous and contaminating chemical mixtures.

| Evaporator surface area | 0,025m², 0,06m², 0,12m², 0,20m² |

| Maximum Operating Temperature |

+220°C (+260°C option available) |

| Operating pressure |

0.1 mbar (abs.) to atmospheric pressure |

| Wiper types |

Roller wiper, folding/pendulum blade wiper, Rotafilm strip wiper |

| Feed type |

Batch feed (up to 2.0L) or continuous feed |

| Feed rate (capacity) |

0,1 to 6,0 kg/h |

Systems

Short Path Evaporator

Short-path evaporation is an advanced technology designed for the efficient separation of high-boiling, temperature-sensitive organic compounds.

| Evaporator surface area |

0,01m², 0,03m², 0,05m², 0,10m², 0,15m², 0,20m² |

| Max. operating temperature |

+220°C (+260°C option available) |

| Operating pressure |

0.1 mbar (abs.) to atmospheric pressure |

| Wiper types |

Roller wiper, folding/pendulum blade wiper, Rotafilm strip wiper |

| Feed type |

Batch feed (up to 2.0L) or continuous feed |

| Feed rate (capacity) |

0,1 to 3,0 kg/h |

Systems

Extraction ECR Column

Continuous liquid-liquid extraction in the extraction column for high separation level in compact spaces.

| Column dimensions |

DN32 (900mm) – DN60 (1400mm) |

| Column type |

Agitated Kühni Column ECR |

| Vessel type |

Single wall, double wall |

| Operating temperature |

+20°C to + 80 °C |

| Coating options |

Breakage protection, Antistatic |

| Wetted materials |

Borosilicate glass 3.3, PTFE, SS316L (PEEK and Hastelloy options available) |

Systems

Falling Film Evaporator

The Falling Film Evaporator is a high-performance solution for R&D and kilo labs, designed to handle sensitive substances with precision and reliability.

| Evaporator surface |

0,04m², 0,06m², 0,12m² |

| Evaporator body length |

380mm (0,04m²), 560mm (0,06m²), 1.120mm (0,12m²) |

| Evaporator body diameter (ID) |

32mm |

| Evaporator type | Single tube system Double wall glass construction |

| Operation type |

Continuous mode or batch mode |

| Max. Temperature | +220°C |

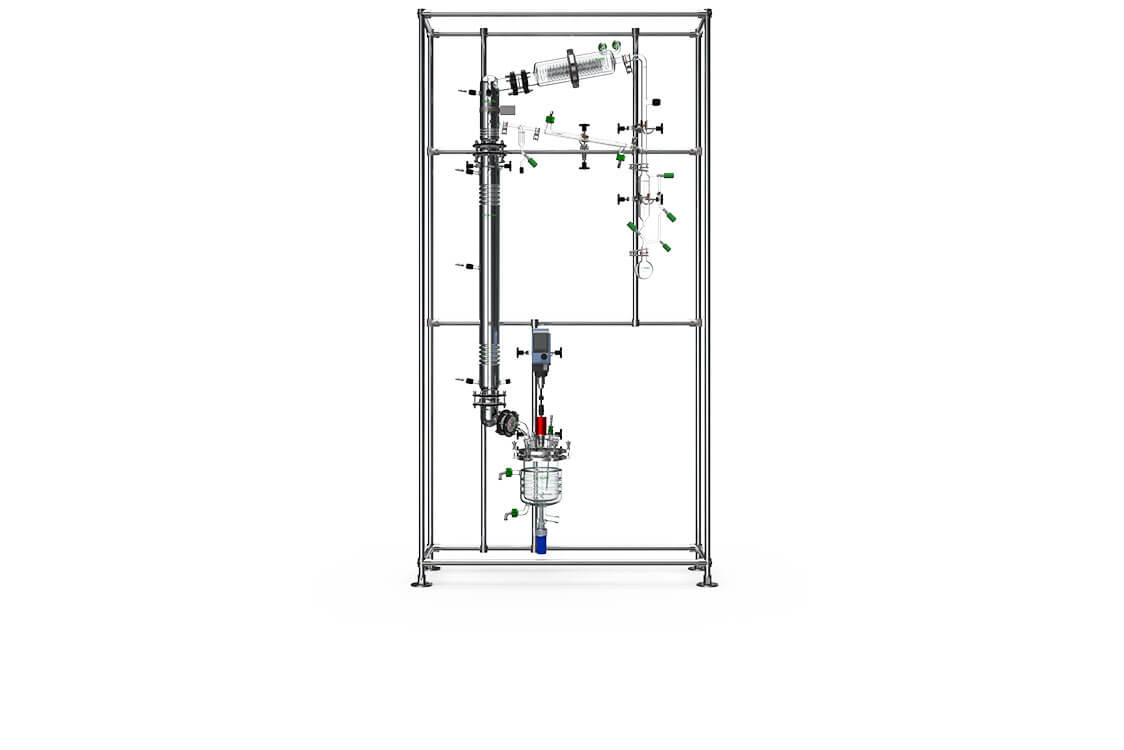

Systems

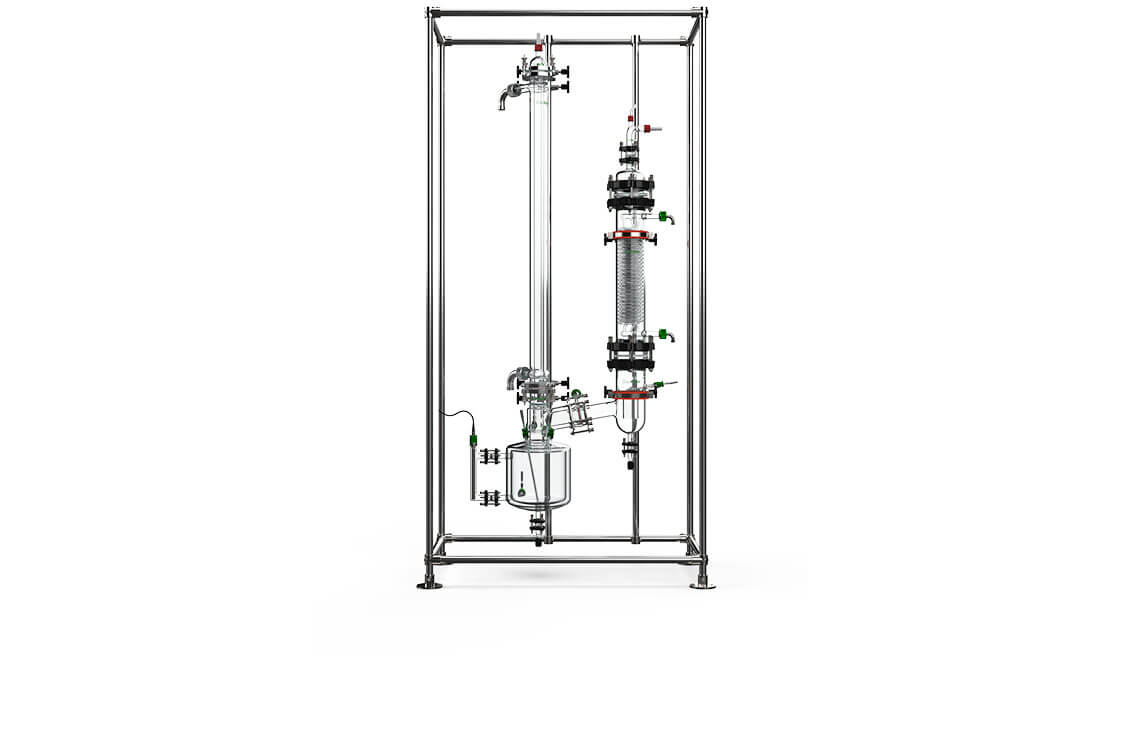

Rectification System

Rectification glass columns are essential for precise and reliable liquid separation, meeting the stringent demands of chemical and pharmaceutical applications.

| System components |

Rectification column, evaporation source, reflux divider (liquid or vapour), vacuum line and vacuum pump, collection reservoir(s) |

| Rectification column diameter |

DN30, DN50, DN70 |

| Rectification column length |

Active segments of 0.5 m and 1.0 m |

| Operating temperature |

Up to 220°C |

| Evaporation source | Jacketed reactor, thin film evaporator or falling film evaporator (dependent on process) |

| Packing type |

Wide range of packing type from multiple suppliers. |

Systems

Filter Reactor

Filter Reactor systems are engineered to meet the challenges of demanding processes where solid handling is required (such as crystallization processes).

| Volume |

200ml – 30L |

| Reactor diameter range |

DN50 – DN300 |

| Reactor type |

Double wall, full jacket |

| Operating temperature |

-30°C to +200 °C |

| Filter | Wide range of pore sizes |

| Coating options |

Breakage protection, Antistatic |

Systems

Customized System

Do you have a project or concept that requires customized glass systems? Work with our team today to turn your idea into a reality.

We support you from the planning of the system through to installation and commissioning with a flexible and competent team.