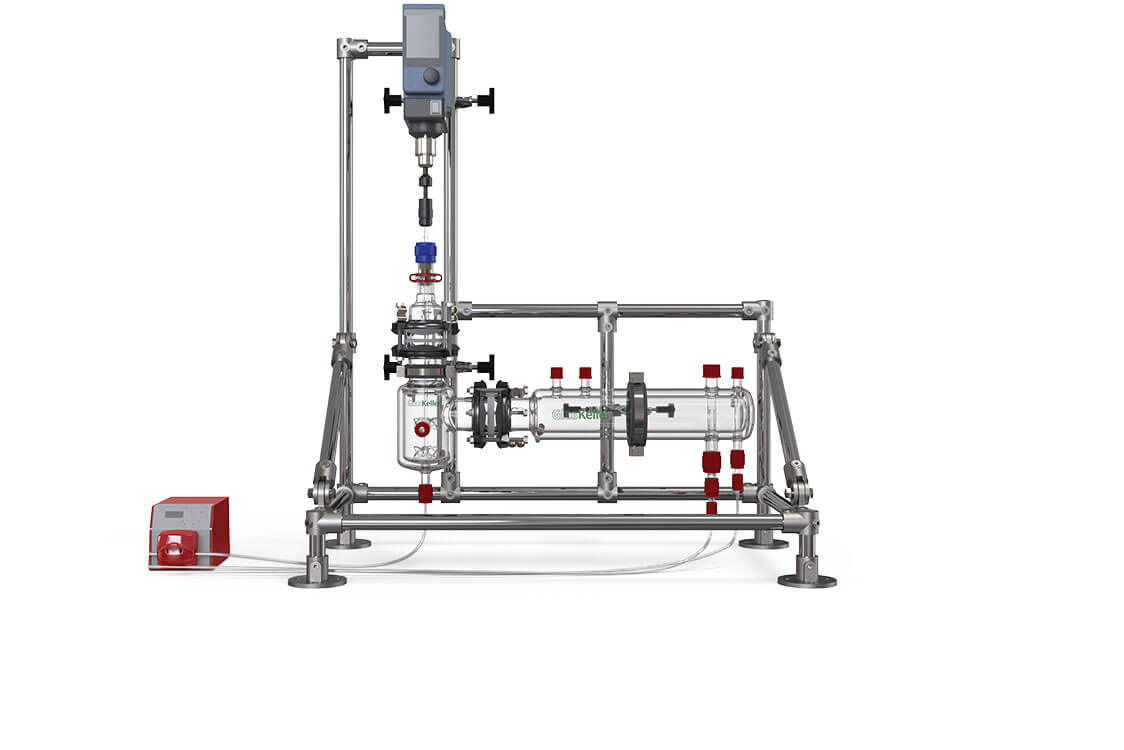

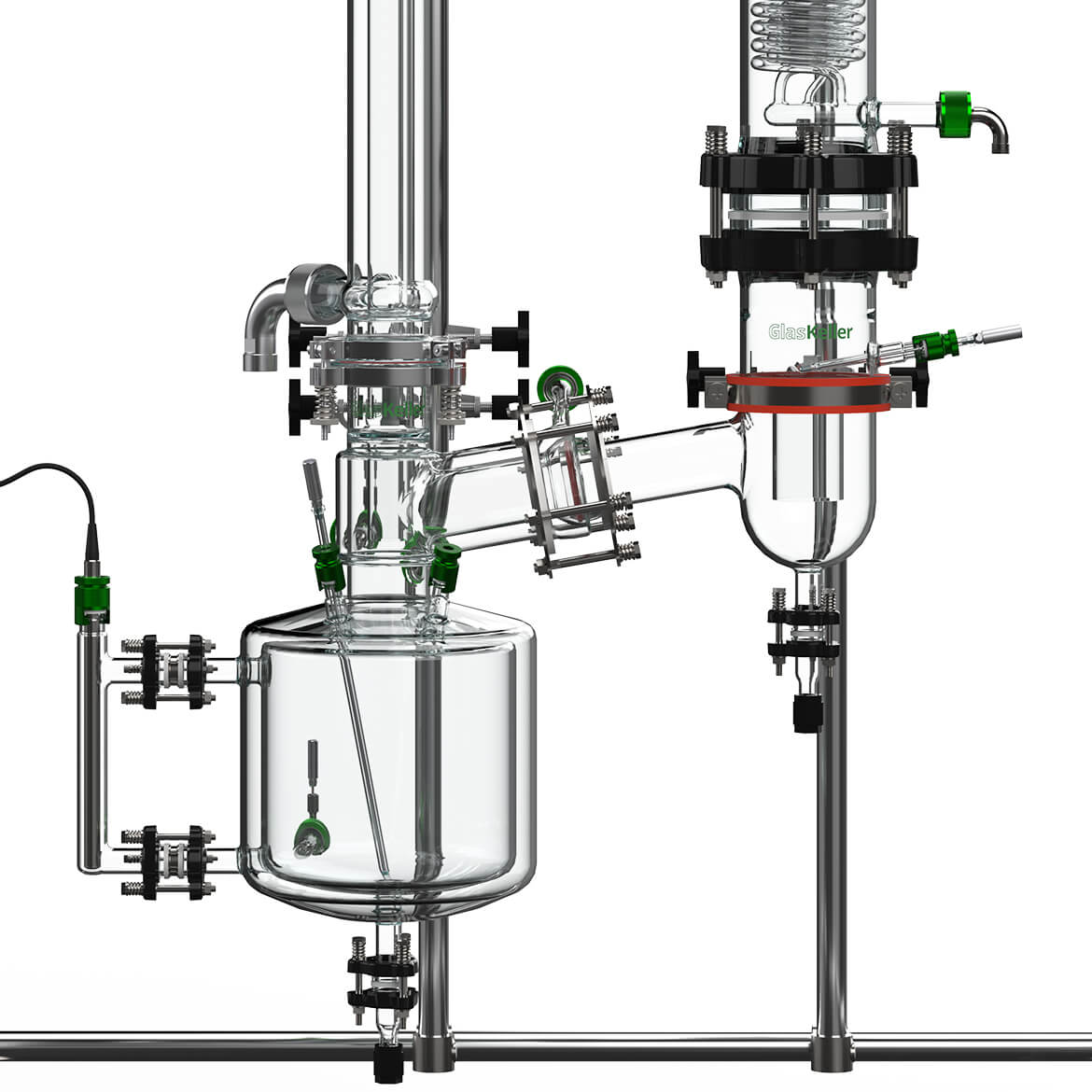

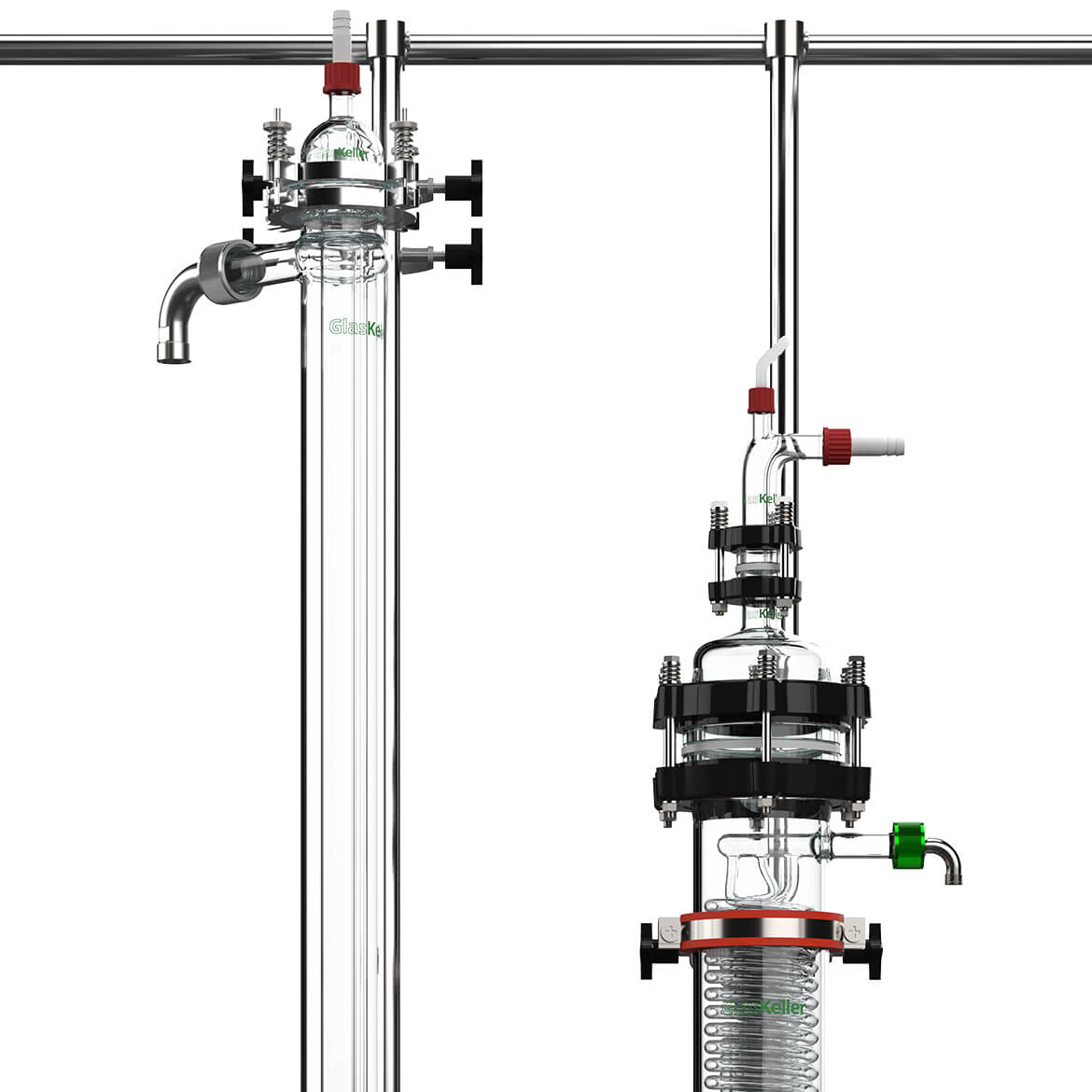

Falling Film Evaporator

Falling film evaporators are high-performance, reliable systems designed for the efficient concentration of large volumes of low- to medium-fouling liquids. With their ability to gently handle temperature-sensitive liquids, they provide an ideal solution for processes requiring both precision and efficiency.

Specification

Evaporator surface

0,04m² , 0,06m² or 0.12m²

Evaporator body length

380mm (0.04m²); 560mm (0.06m²), 1,120mm (0.12m²)

Evaporator body diameter (ID)

32mm

Evaporator type

Single tube system

Double wall glass construction

Operation type

Continuous mode or batch mode

Reservoir volume

Volume dependent on process (maximum volume 10 L)

Max. Temperature

+220°C

Operating pressure

Vacuum (5.0 mbar) to atmospheric pressure

Wetted materials

Borosilicate glass 3.3, (Stainless Steel 316L and Hastelloy options available)

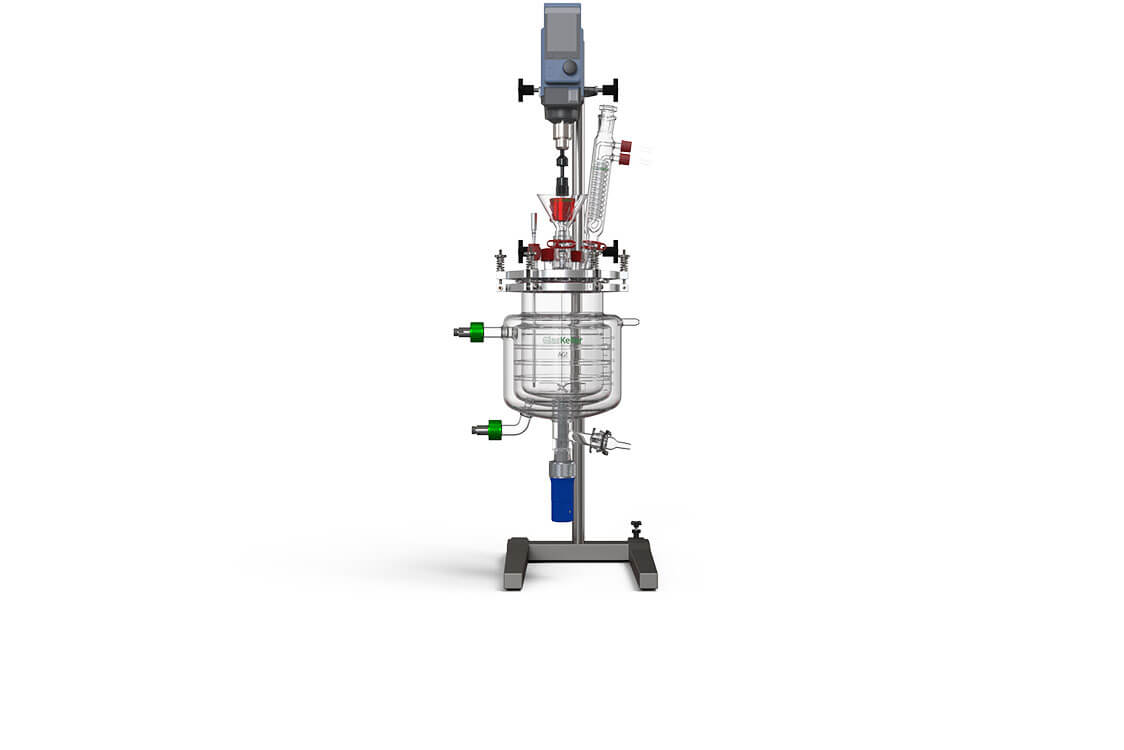

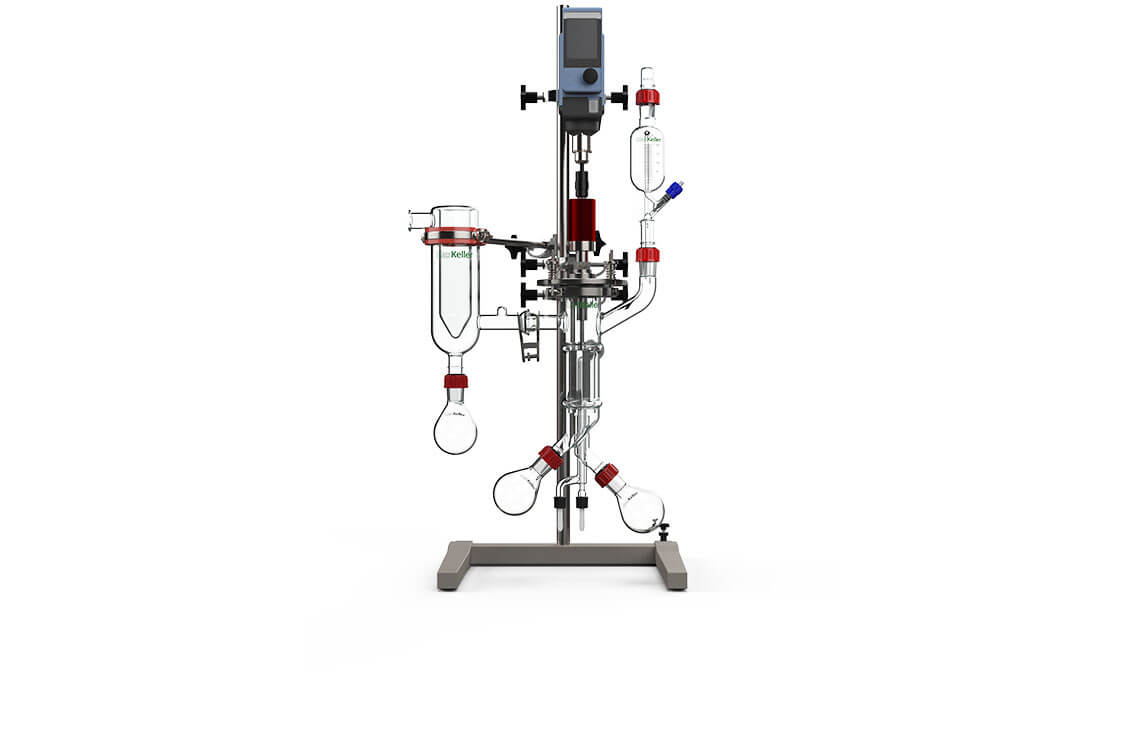

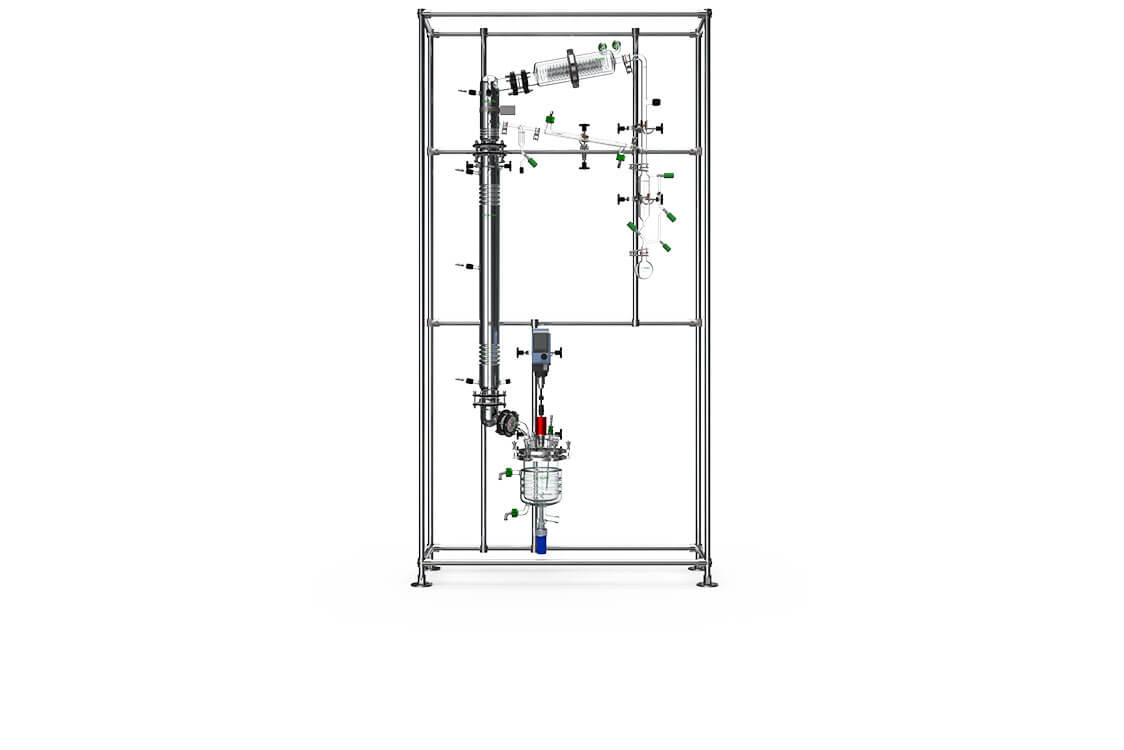

The GlasKeller Falling Film Evaporator is a high-performance solution for R&D and kilo labs, designed to handle sensitive substances with precision and reliability. Its innovative technology enables efficient evaporation of diluted solutions and facilitates the separation of complex substance mixtures when combined with vacuum-operated separation columns. By utilizing a continuously flowing liquid film that slides down the heated tube’s inner wall, the evaporator ensures seamless performance for demanding applications. This evenly distributed film maximizes heat transfer and evaporation efficiency, making the system particularly suitable for thermally sensitive substances like foodstuffs, pharmaceuticals, and specialty chemicals.

With a short dwell time and controlled temperatures, it safeguards the integrity of sensitive products, ensuring consistent and gentle processing for delicate compounds.

Special liquid distribution systems guarantee uniform film formation during the process, while vapour components are continuously removed to prevent residue buildup. Designed with minimal pressure loss and exceptional energy efficiency, the falling film evaporator is a trusted choice in industries such as food production, fruit juice manufacturing, and chemical separation, offering unparalleled quality and performance.

Tailored Solutions for Sensitive Processing

Short dwell times combined with low operating temperatures prevent thermal decomposition, ensuring outstanding product quality. GlasKeller Basel AG’s falling film evaporators feature a modular design and precise temperature control, making them adaptable to specific process requirements.

These evaporators excel in industries requiring continuous and efficient separation processes, such as food production, pharmaceutical manufacturing, and chemical applications. They deliver gentle, energy-efficient processing, safeguarding the integrity of sensitive substances across various uses.

MESSAGE US

We are here to help

Whether you are an existing customer looking to reproduce your glassware or someone with an entirely new challenge, we deliver unbeatable product quality and excellent support from enquiry to delivery, and beyond.

Contact us to get started.