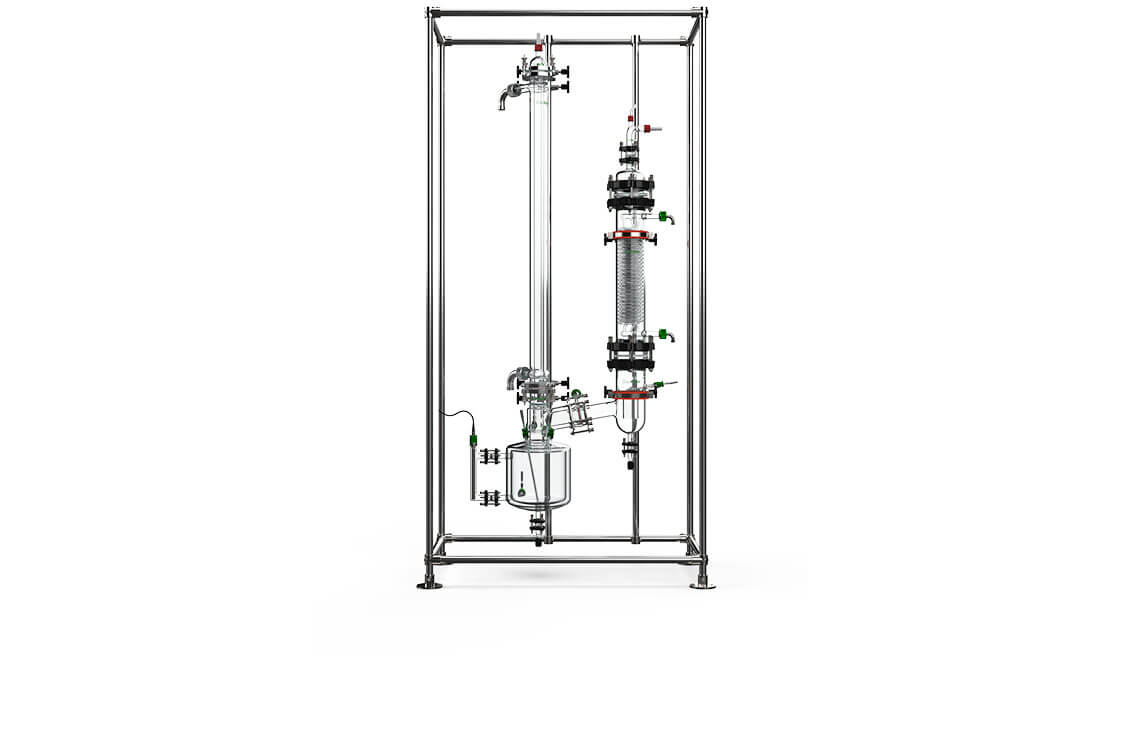

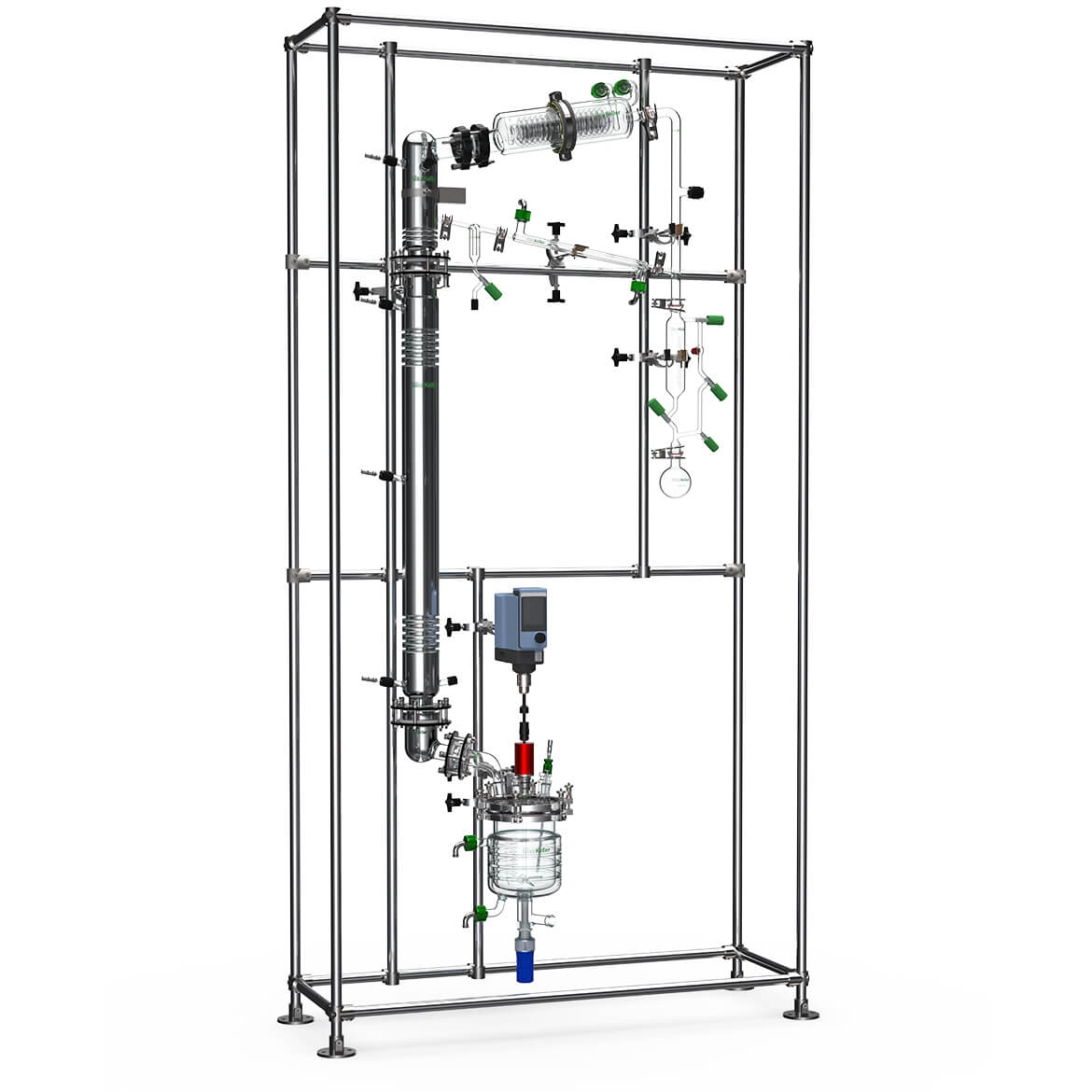

Rectification System

The GlasKeller Rectification glass columns are essential for precise and reliable liquid separation, meeting the stringent demands of chemical and pharmaceutical applications. Utilizing multi-stage distillation, they ensure efficient, clean separation while offering transparency for monitoring. Designed for durability, they deliver consistent performance in research and industrial operations. GlasKeller provides tailored solutions to enhance efficiency, precision, and control throughout your process.

Specification

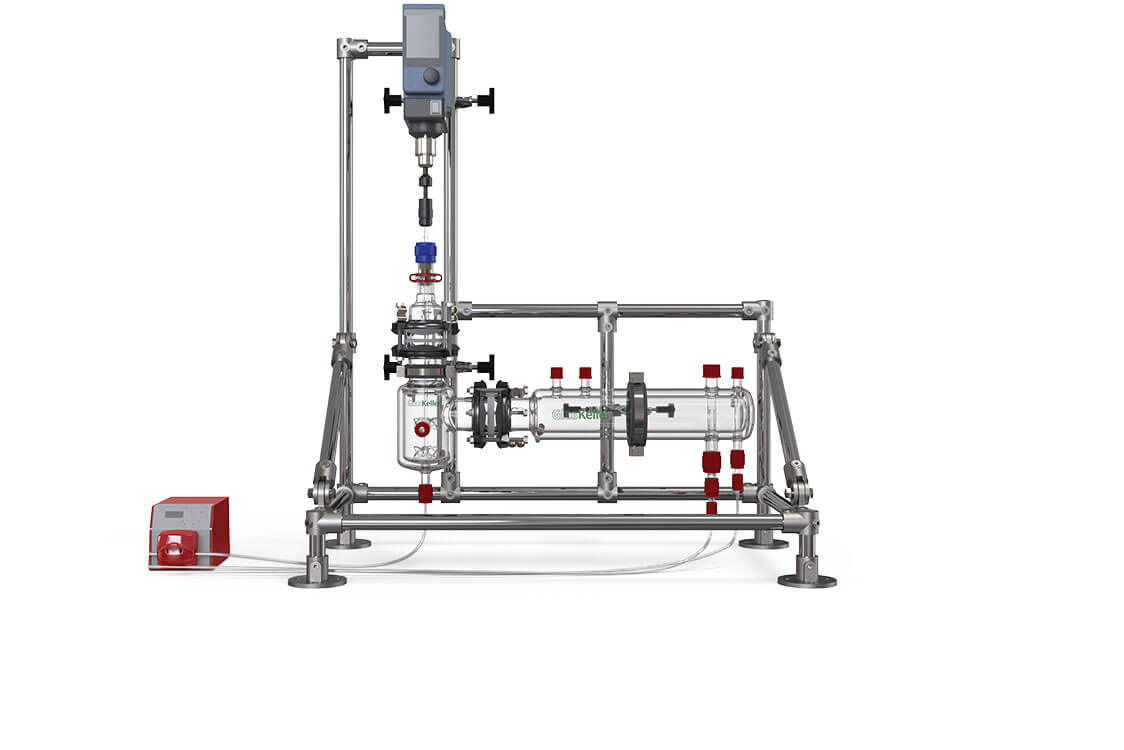

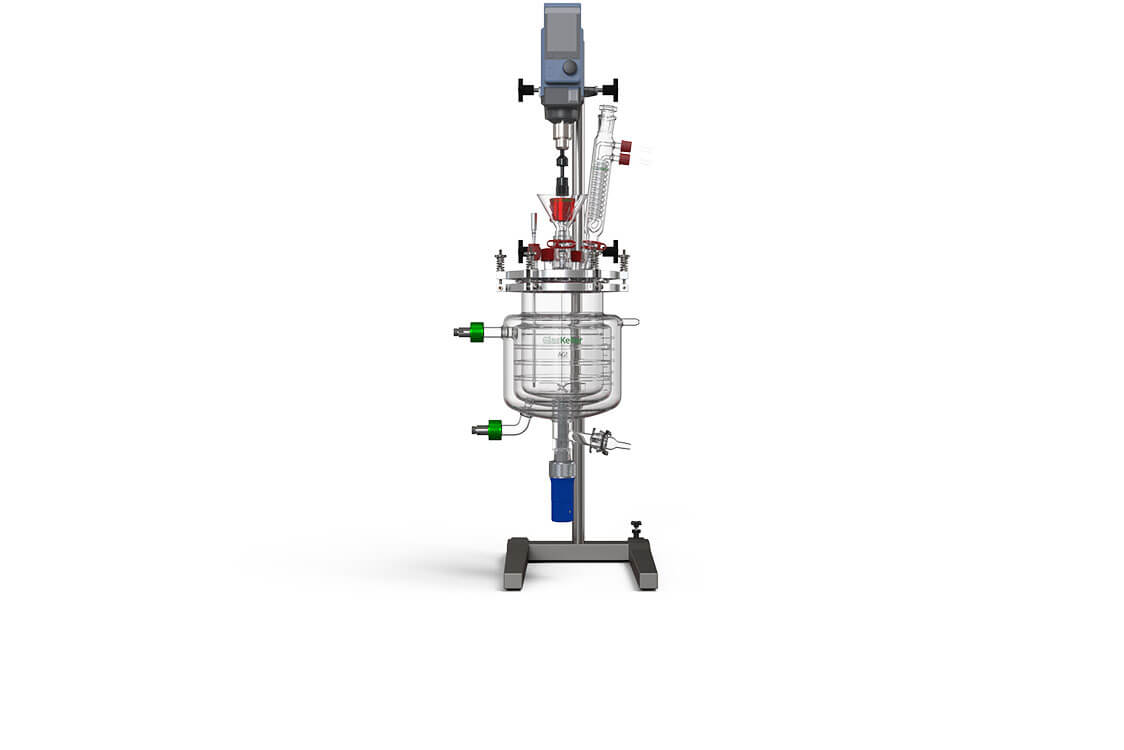

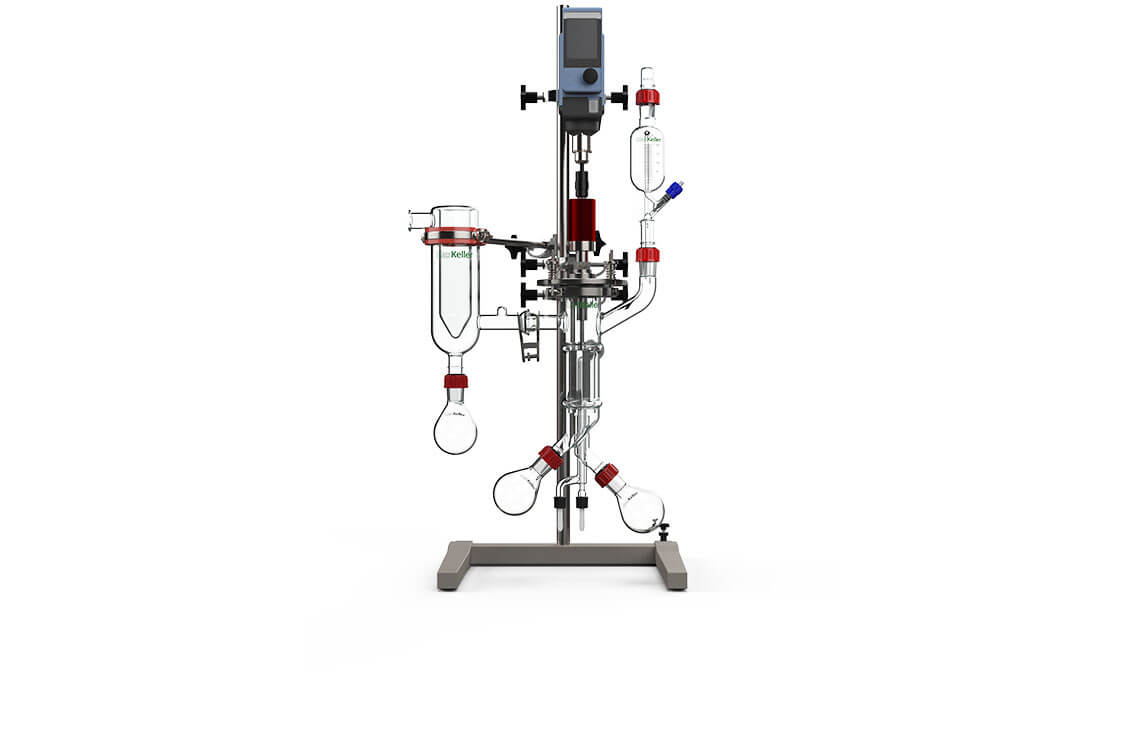

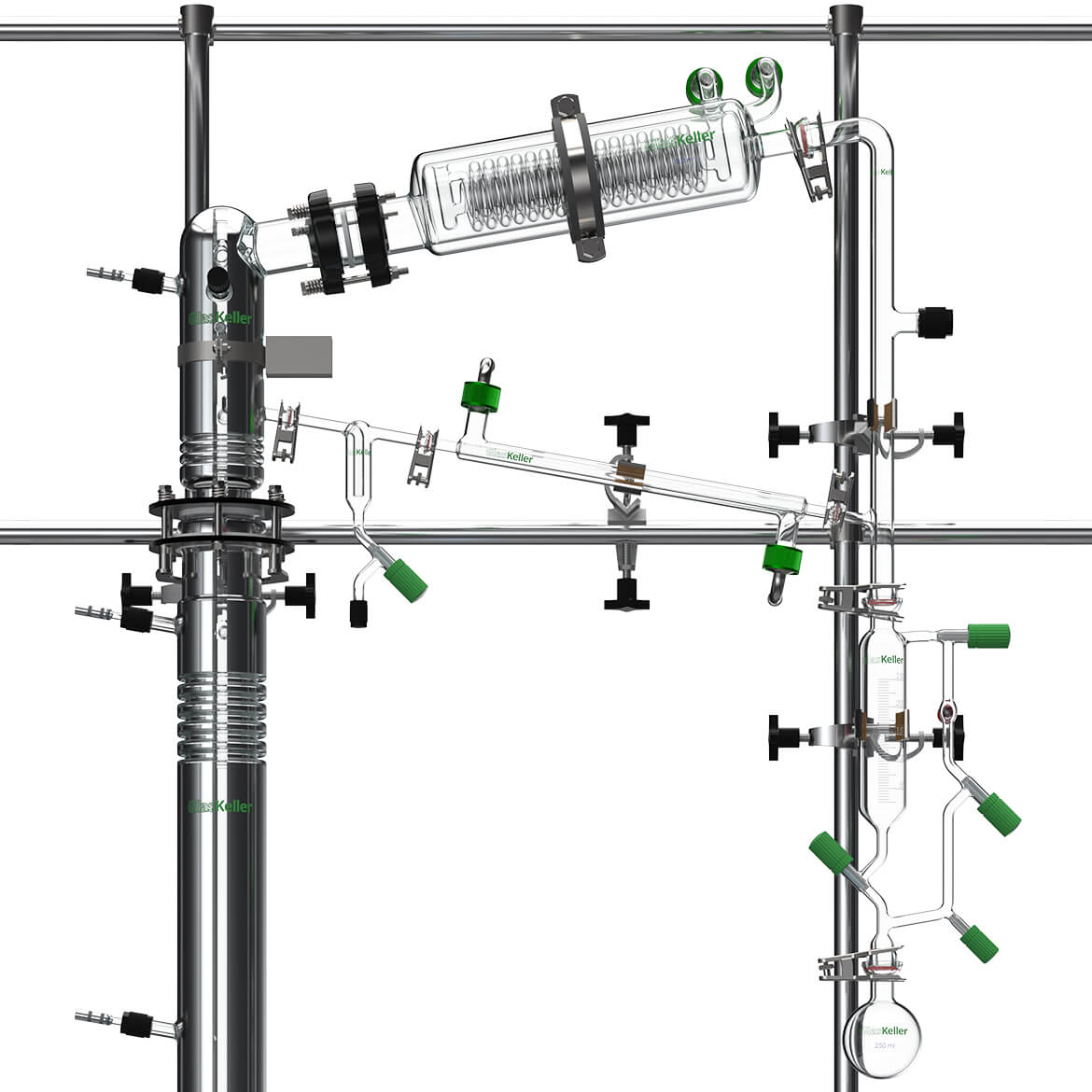

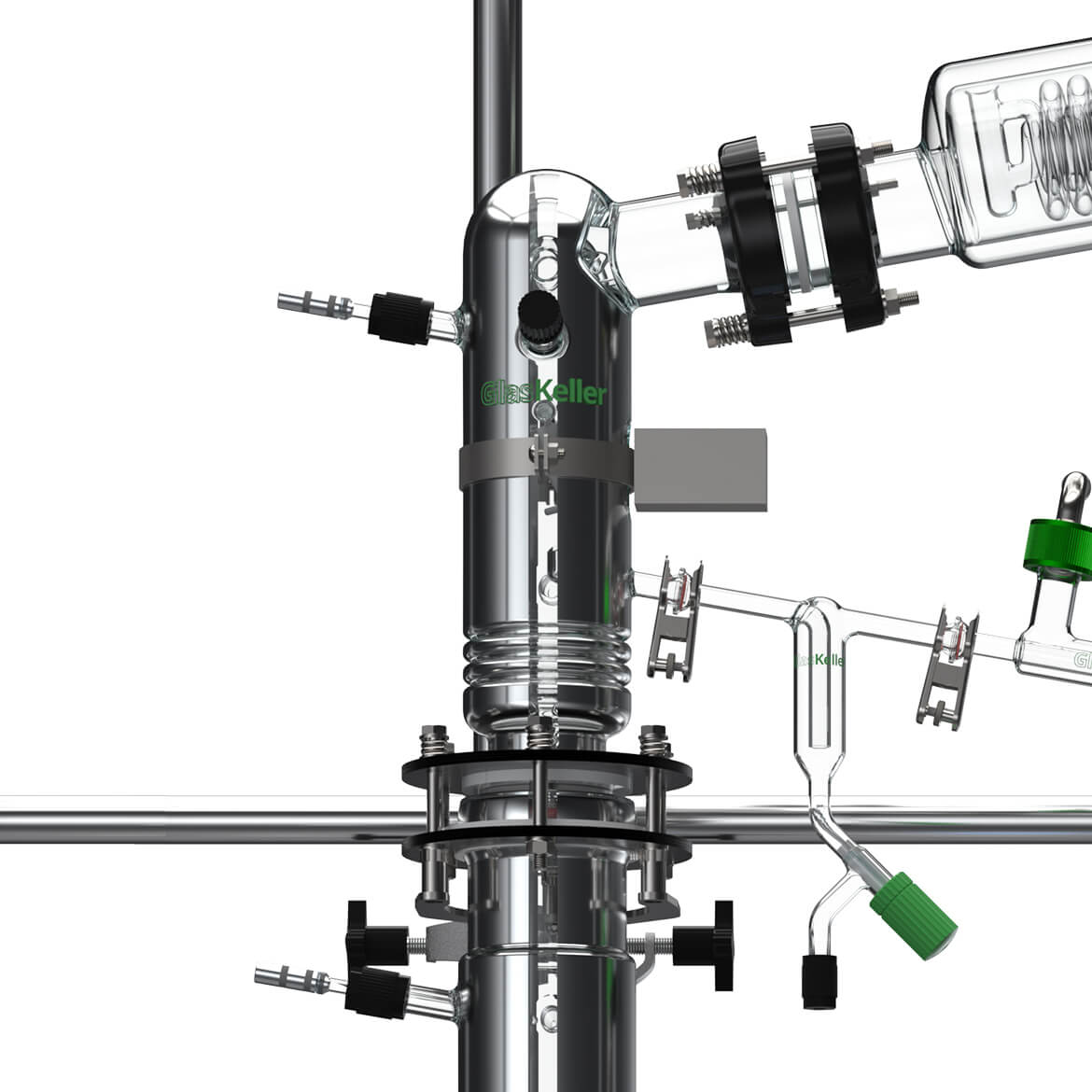

System components

Rectification column, evaporation source, reflux divider (liquid or vapour), vacuum line and vacuum pump, collection reservoir(s)

Rectification column diameter

DN30, DN50, DN70

Rectification column length*

Active segments of 0.5 m and 1.0 m

Evaporation source

Jacketed reactor, thin film evaporator or falling film evaporator (dependent on process)

Operating temperature

Up to 220°C

Operating pressure

Full vacuum to atmospheric pressure

Packing type**

Wide range of packing type from multiple suppliers including (but not limited to): structured packing, random packing, sieve tray, bell shape

Packing material

Hastelloy, SS316L, Glass, Graphite, Polymers (wide range), Ceramic

Packing material dependent on customer process

Column type and material

Vacuum jacketed and silver coated borosilicate glass 3.3 column

*Column length is determined by number of active segments in column. Number of segments used depends on the process.

**Packing material is dependent on the process. GlasKeller will assist with choosing the correct packing material.

Rectification systems play a vital role in the separation and purification of liquid mixtures with exceptional precision. Through the process of multi-stage distillation, even minute differences in boiling points are accounted for, enabling highly efficient and clean separation. This precision is essential for achieving the desired level of purity and consistency in various applications.

Whether used in chemical manufacturing, pharmaceutical research, or the production of flavors and solvents, these systems consistently deliver reliable results that adhere to stringent quality standards. With continuous process monitoring, operators can maintain stable performance and exercise maximum control over the separation process, ensuring dependable outcomes every time.

Designed for efficiency, the mirrored and vacuumed jacket minimizes heat loss, enhancing overall energy performance. The system’s flexibility is further demonstrated by its compatibility with various packing elements, allowing for feasibility studies using laboratory packings or the generation of data for production-scale plant design. By integrating multiple column sections, the system can address a wide range of complex separation tasks with ease and accuracy.

GlasKeller – expertise in supporting your process

With years of experience in the chemical and pharmaceutical industries, GlasKeller is a trusted partner in supplying rectification and separation process systems. Our team combines technical expertise with a deep understanding of industry demands, ensuring tailored solutions for your unique applications At GlasKeller, we are dedicated to providing innovative and practical solutions that enhance efficiency and precision at every stage.

MESSAGE US

We are here to help

Whether you are an existing customer looking to reproduce your glassware or someone with an entirely new challenge, we deliver unbeatable product quality and excellent support from enquiry to delivery, and beyond.

Contact us to get started.