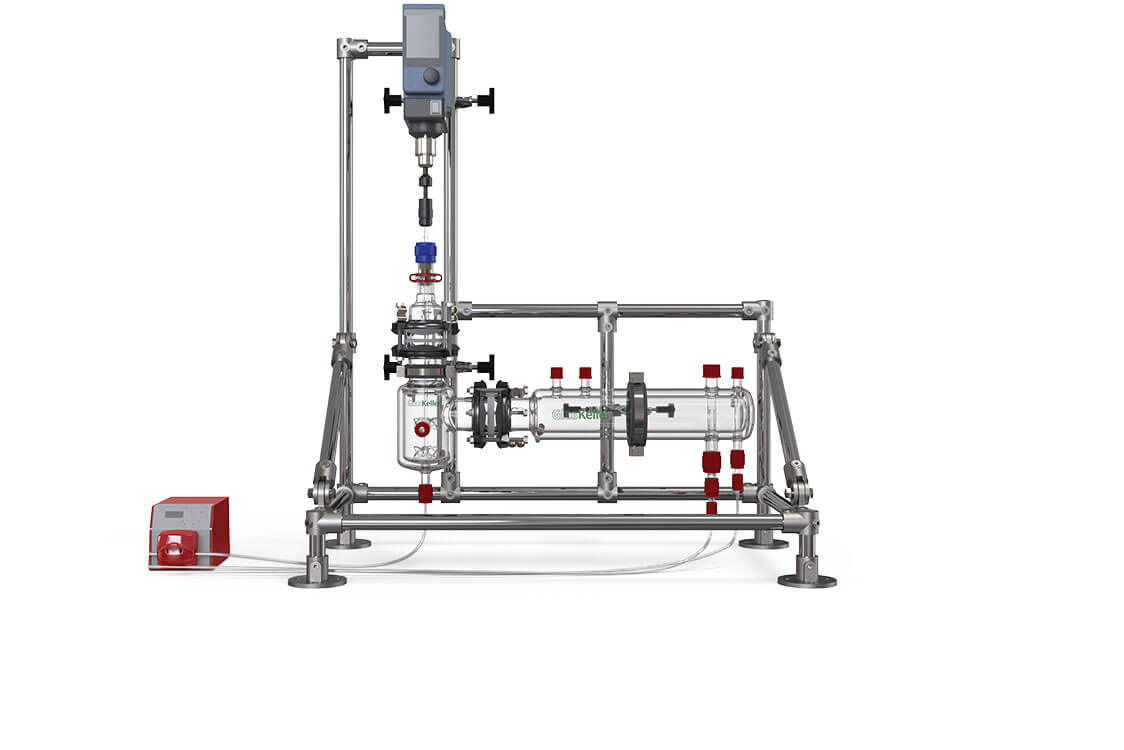

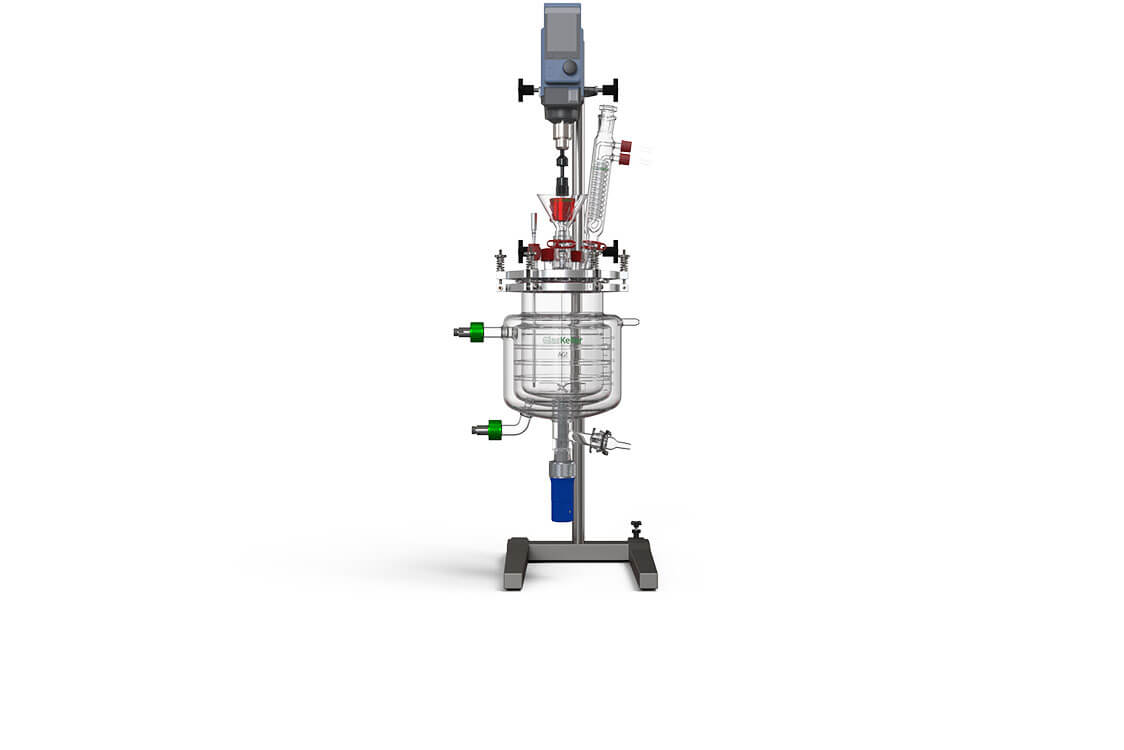

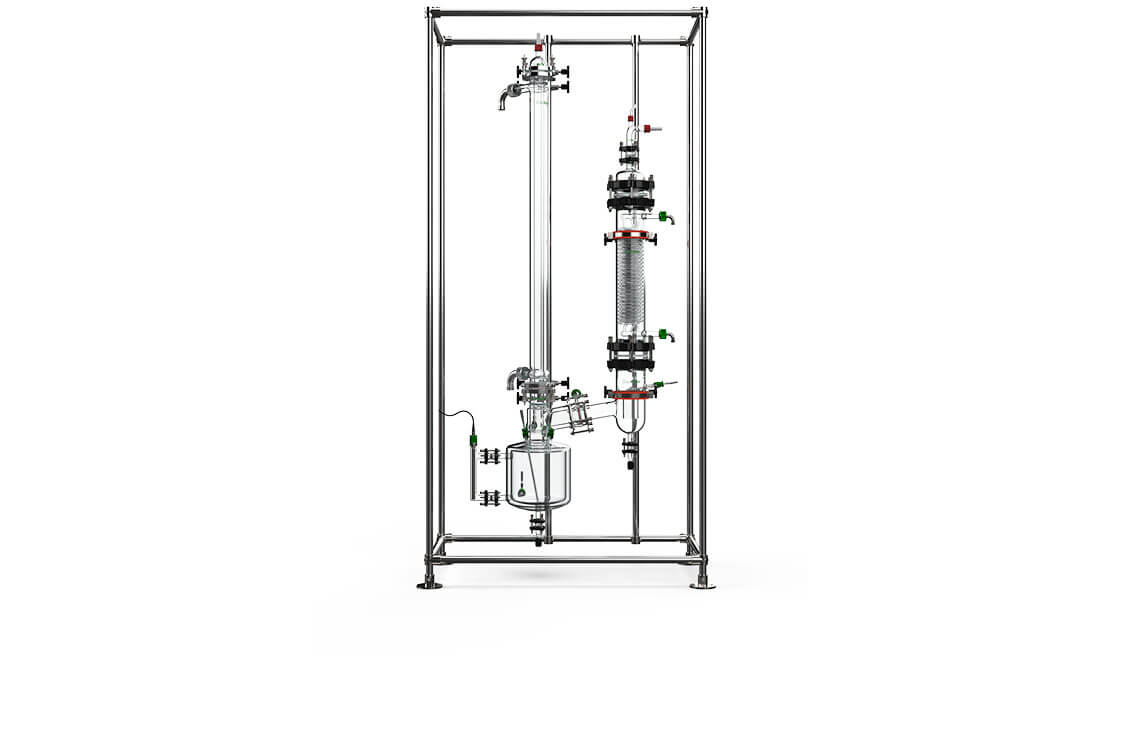

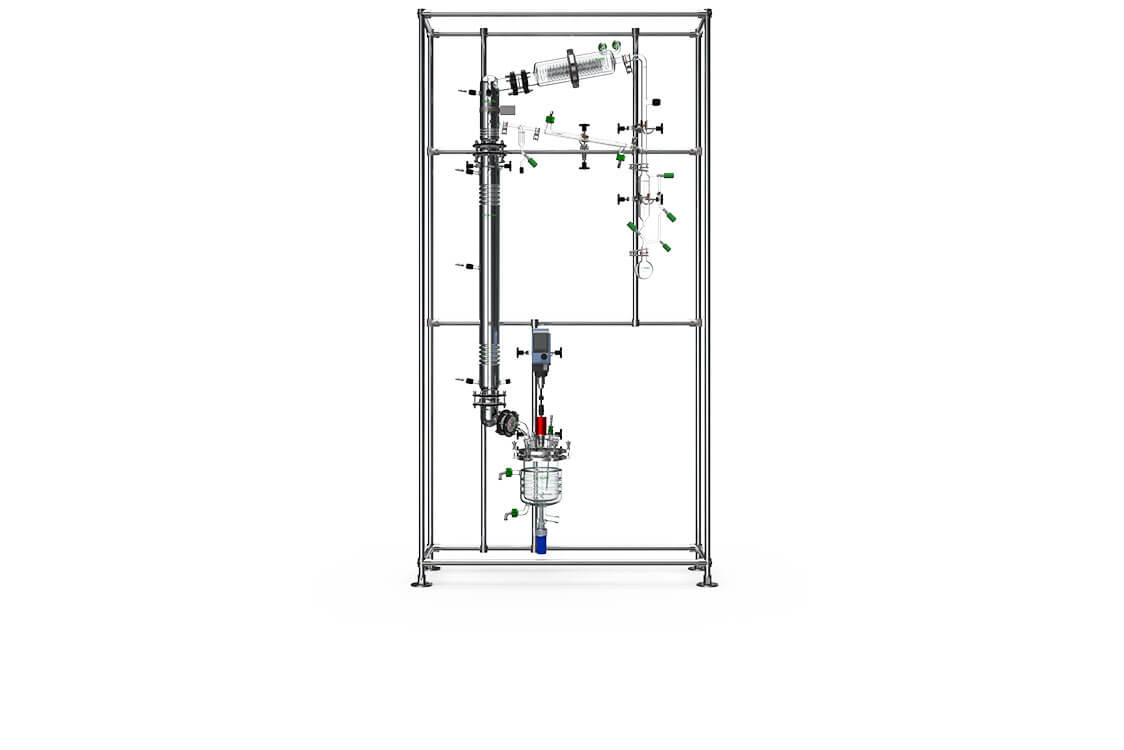

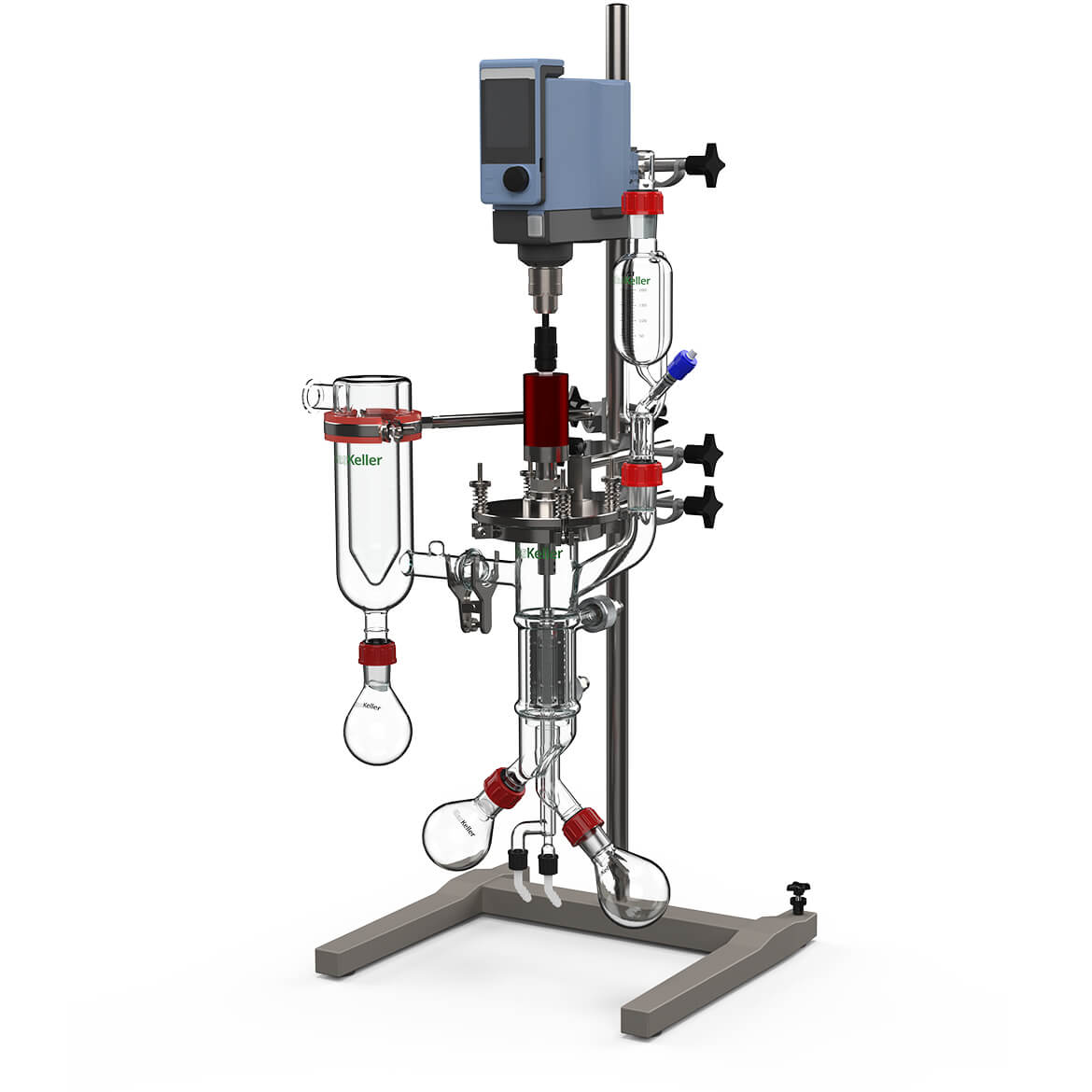

Short Path Evaporator

Short-path evaporation is an advanced technology designed for the efficient separation of high-boiling, temperature-sensitive organic compounds. Operating under ultra-fine vacuum conditions (up to 1×10⁻³ mbar), its innovative design minimizes heat load through reduced distances between the evaporator tube and integrated condenser. The system’s high-quality glass construction ensures exceptional process visibility, allowing precise adjustments to feed rates for optimal control and reliability.

Specification

Evaporator surface area*

0,01m², 0,03m², 0,05m², 0,10m², 0,15m², 0,20m²

Maximum Operating Temperature

+220°C (+260°C option available)

Operating pressure

0.001 mbar (abs.) to atmospheric pressure

Wiper types

Roller wiper, folding/pendulum blade wiper, Rotafilm strip wiper

Wetted materials

Borosilicate glass 3.3, PTFE, stainless steel 316

(Hastelloy options available)

Operation type

Batch feed (up to 2.0L) or continuous feed

Feed rate (capacity)

0.1 to 3.0 kg/h

Max. Max. viscosity at operating temperature

Up to 1,000 mPa.s (custom)

*custom sizes available

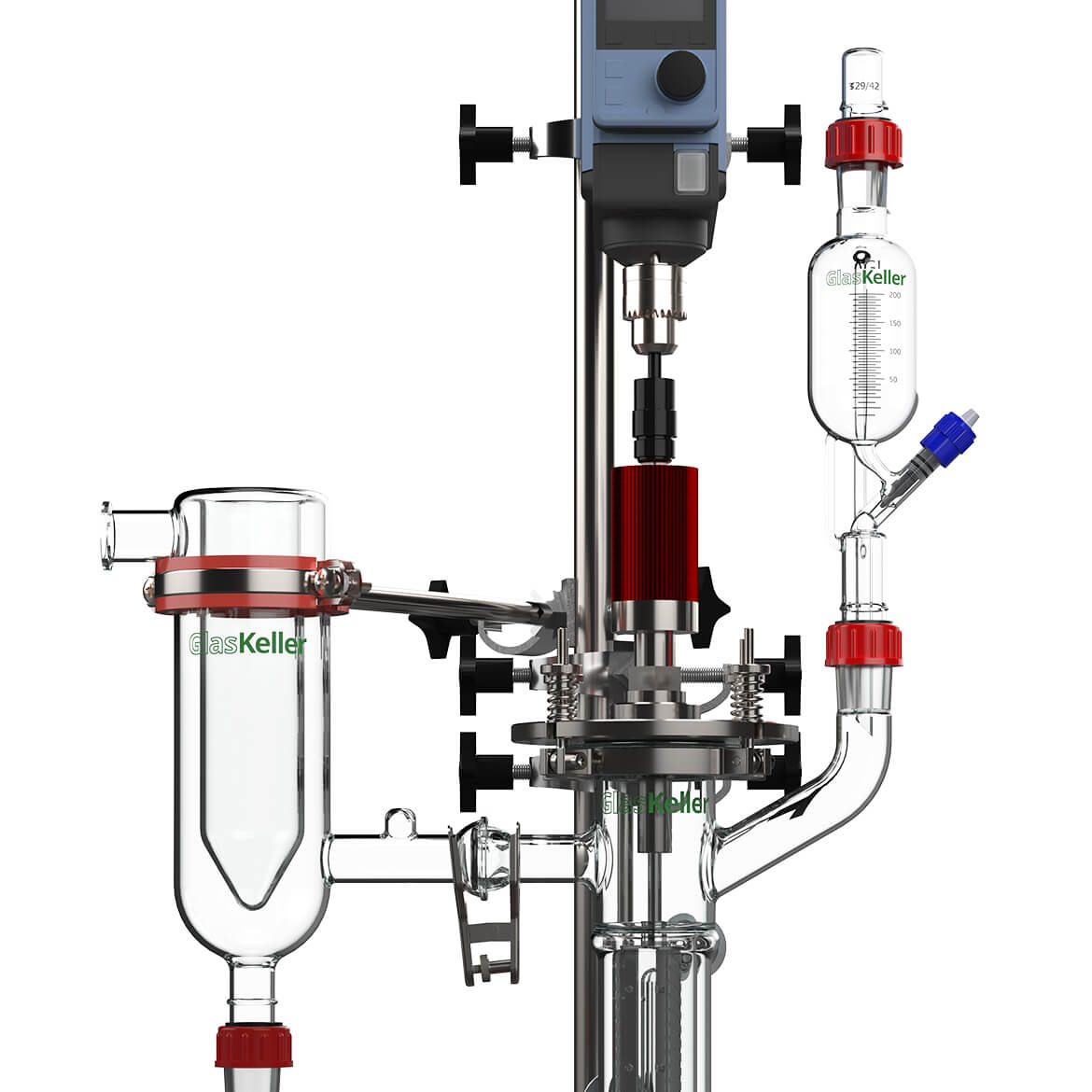

The short path evaporator is specifically designed for sensitive substances such as active pharmaceutical ingredients, essential oils, and specialty chemical products. Its precise method ensures gentle processing, starting with the controlled supply of the feed mixture into the evaporator tube. An optional pre-degasser can be used to remove unwanted gases or low boilers, enhancing preparation.

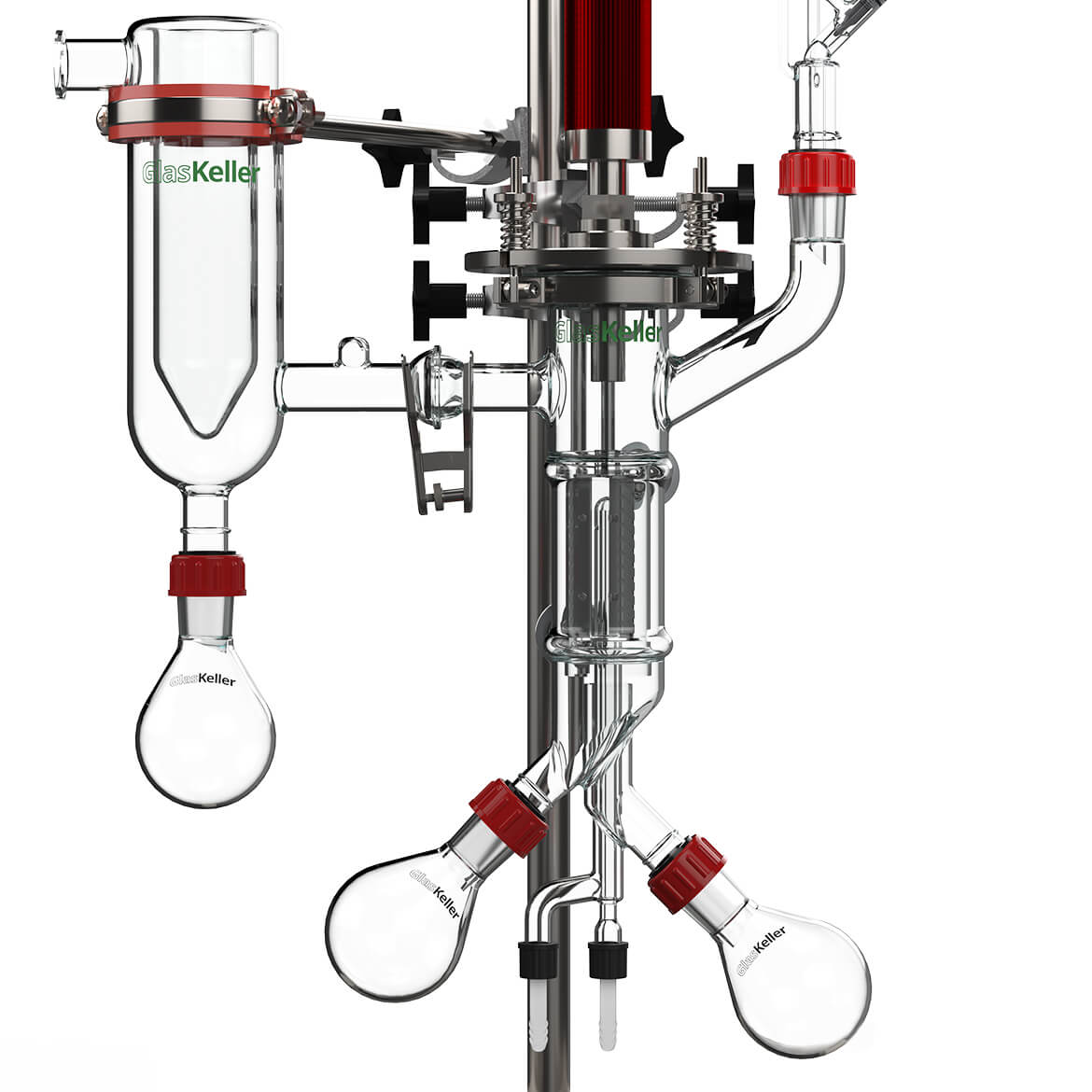

Inside the evaporator, a rotating wiper system spreads the liquid as a continuously renewed thin film, maximizing heat transfer and evaporation efficiency. The short dwell time of molecules in the hot gas phase minimizes thermal stress, safeguarding the integrity of heat-sensitive substances throughout the process.

Reliable Solutions for High-Purity Separation

Short path evaporators are expertly designed for precise separation, efficiently condensing highly volatile components (low boilers) into distillates while isolating heavier residues. The minimal distance between the evaporator and condenser ensures optimized separation, making these systems ideal for demanding processes in pharmaceutical production, cosmetics formulation, and fine chemical applications.

Featuring advanced design elements like double-walled heating zones, temperature-controlled drains, and state-of-the-art vacuum pump systems, these evaporators provide unparalleled efficiency and quality. Their interchangeable wipers, constructed from durable materials such as metal, plastic, or glass, are connected via a magnetic coupling for seamless adaptability to varying media types. With exceptional corrosion resistance and media compatibility, these systems offer tailored solutions for complex applications while upholding the highest purity standards.

MESSAGE US

We are here to help

Whether you are an existing customer looking to reproduce your glassware or someone with an entirely new challenge, we deliver unbeatable product quality and excellent support from enquiry to delivery, and beyond.

Contact us to get started.