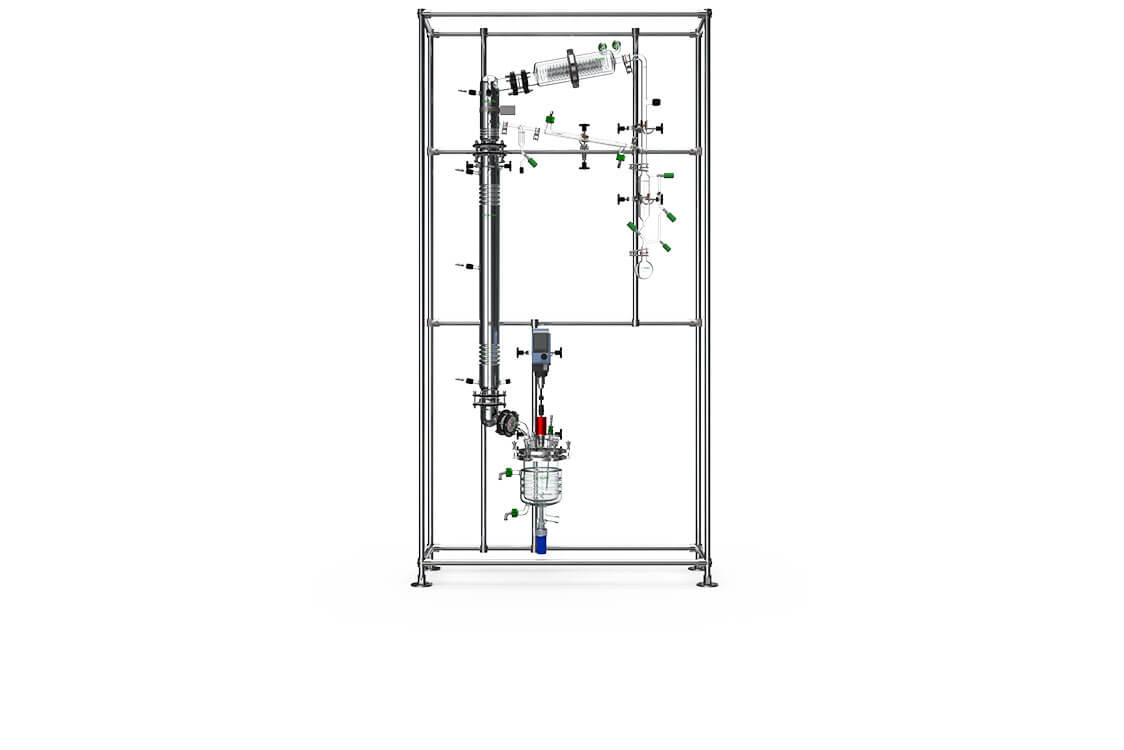

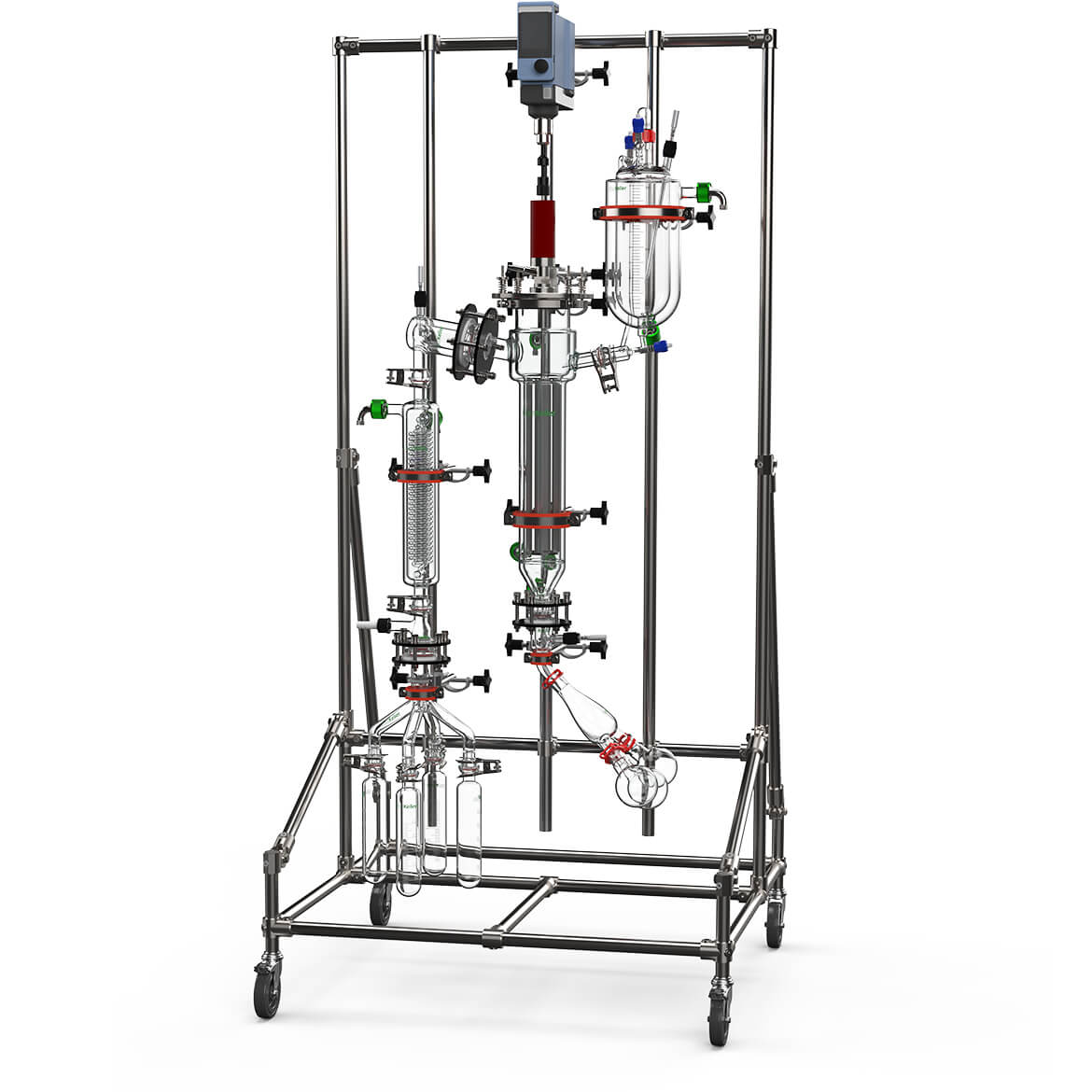

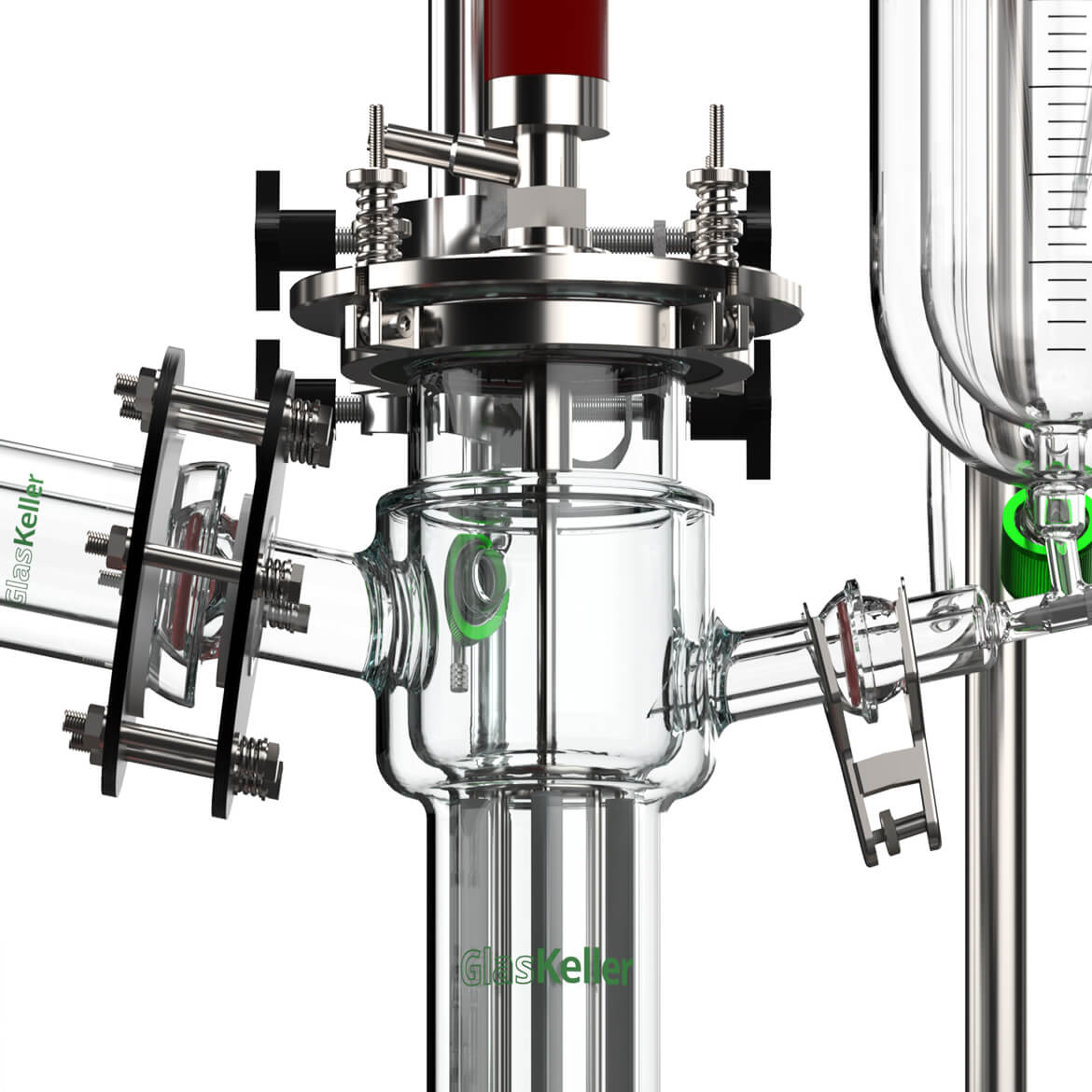

Thin Film Evaporator

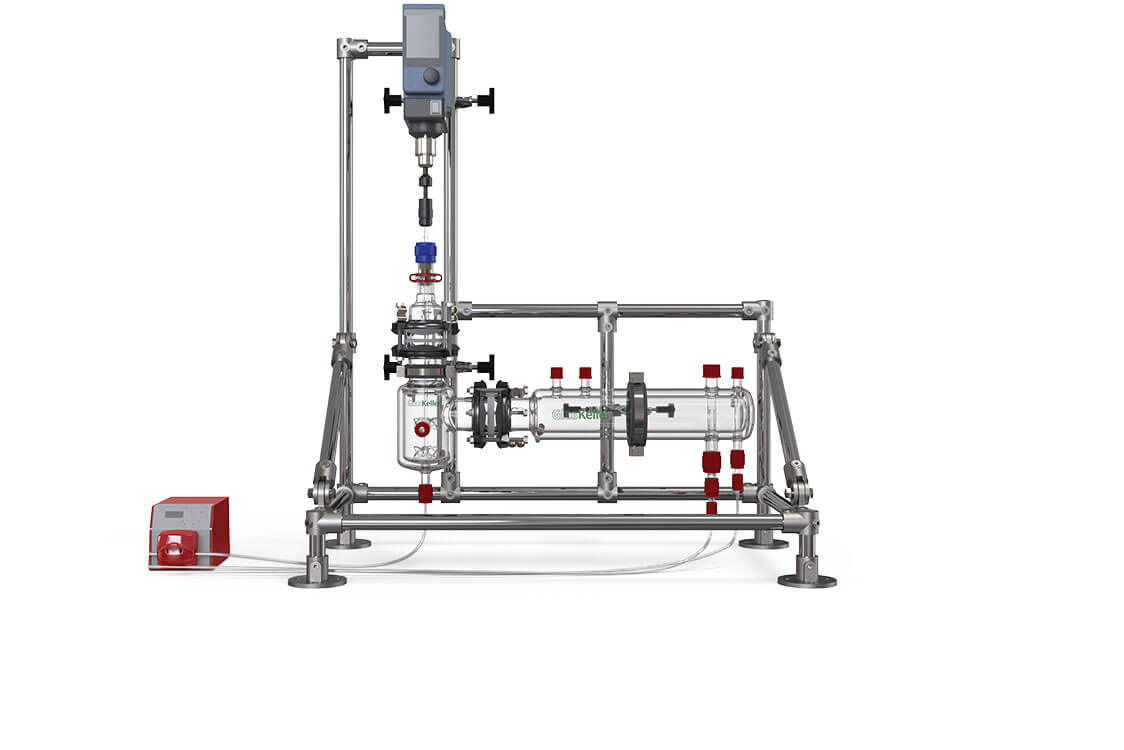

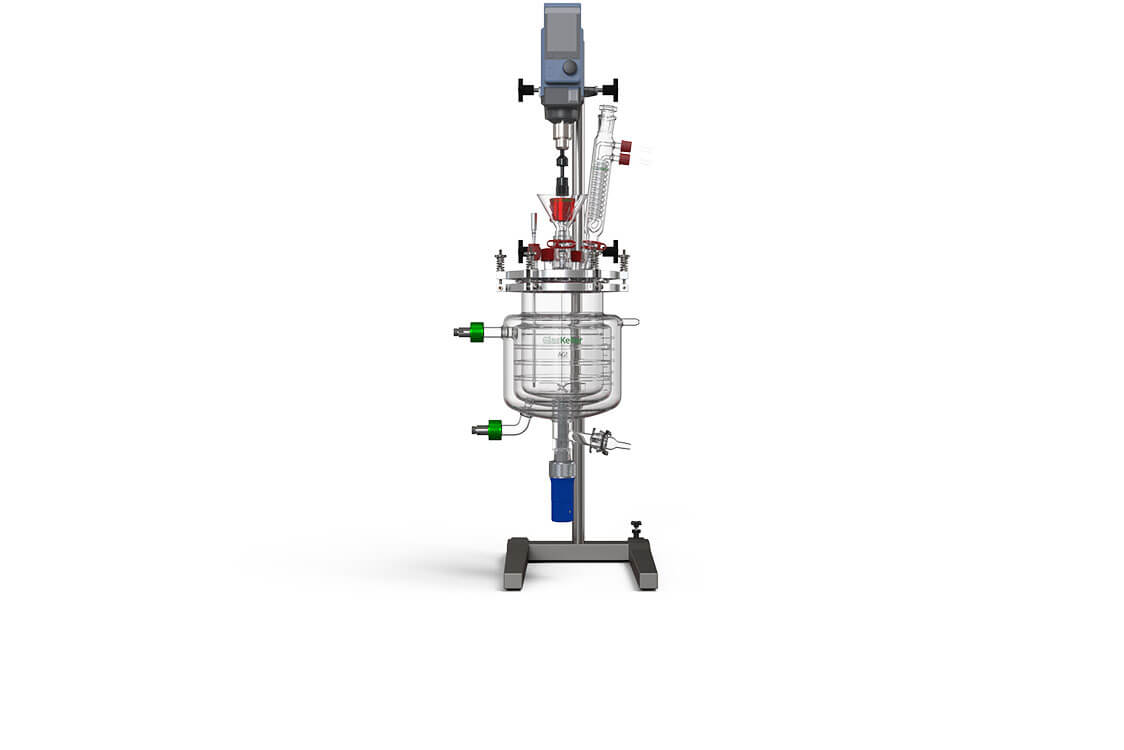

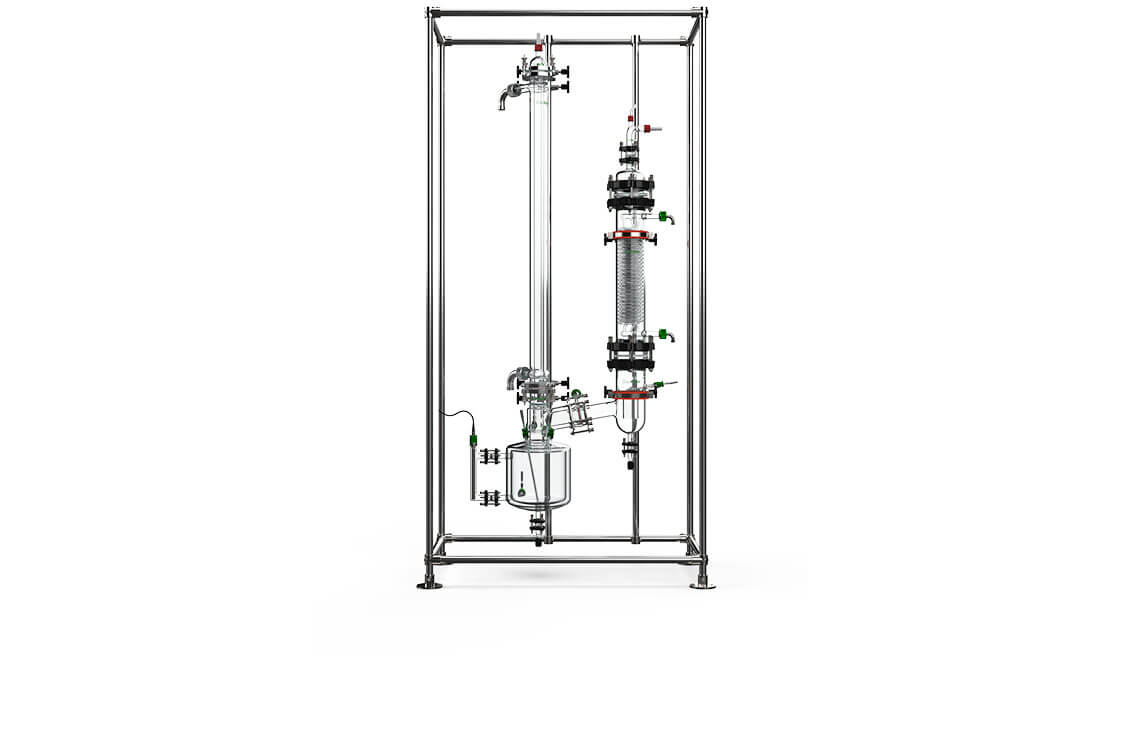

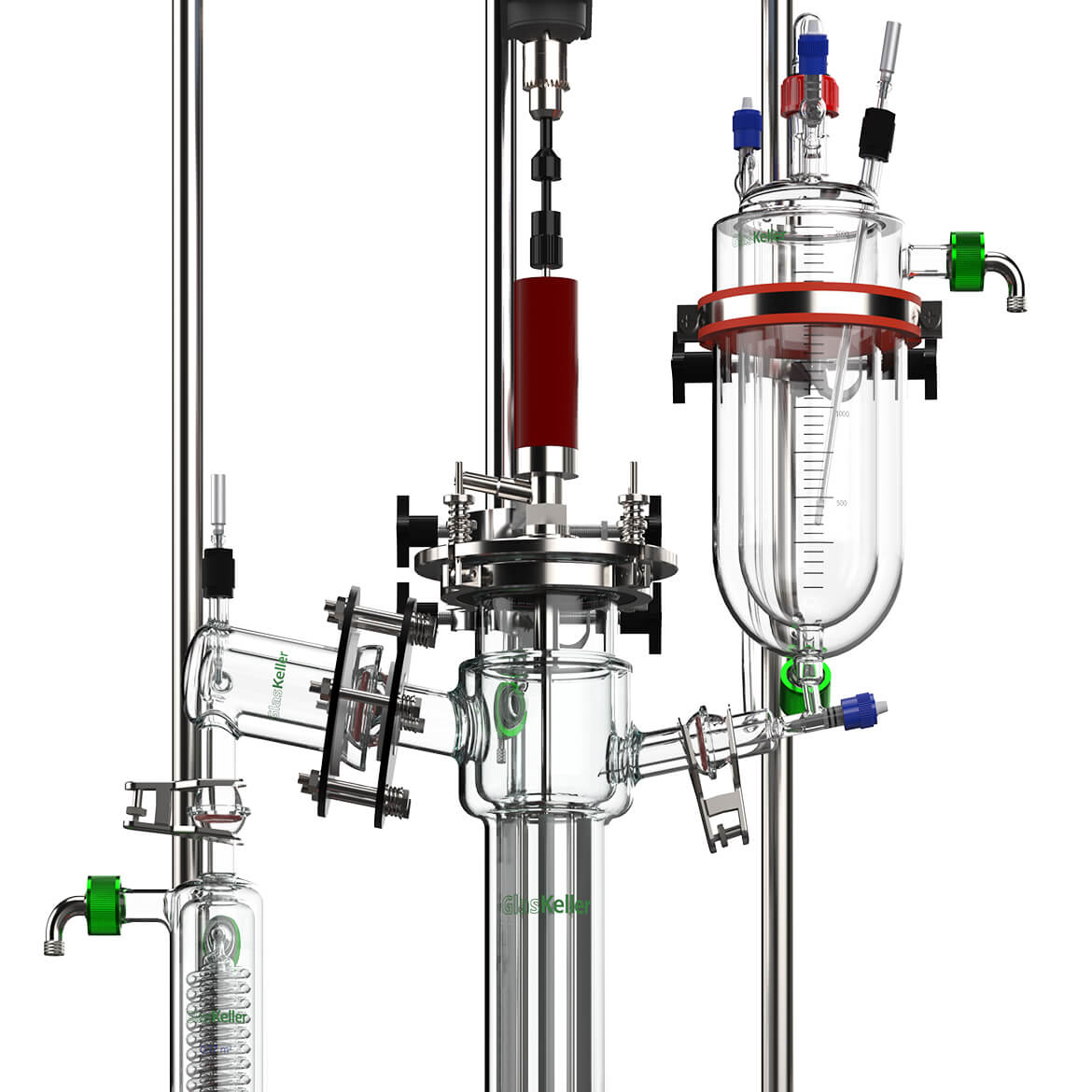

The Thin Film Evaporator (TFE) from GKB is designed for the efficient separation of volatile components from heat-sensitive, viscous, and fouling chemical mixtures. Also known as a Wiped Film Evaporator, it uses PTFE wipers to create a thin film under low pressure minimizing thermal degradation by ensuring short residence times and enabling evaporation at reduced temperatures.

Specification

Evaporator surface area*

0,025m², 0,06m², 0,12m², 0,20m²

Maximum Operating Temperature

+220°C (+260°C option available)

Operating pressure

0.1 mbar (abs.) to atmospheric pressure

Wiper types

Roller wiper, folding/pendulum blade wiper, Rotafilm strip wiper

Wetted materials

Borosilicate glass 3.3, PTFE, stainless steel 316L

(Hastelloy options available)

Feed type

Batch feed (up to 2.0L) or continuous feed

Feed rate (capacity)

0.1 to 6.0 kg/h

Max. Max. viscosity at operating temperature

Up to 1,000 mPa.s (custom)

*custom sizes available

The GKB Thin Film Evaporator ensures efficient heat transfer through a highly turbulent liquid layer, while its short and narrow residence time spectrum protects heat-sensitive products from thermal degradation. This makes it an excellent solution for applications in the chemical, pharmaceutical, and food industries, offering a combination of reliability, flexibility, and product safety.

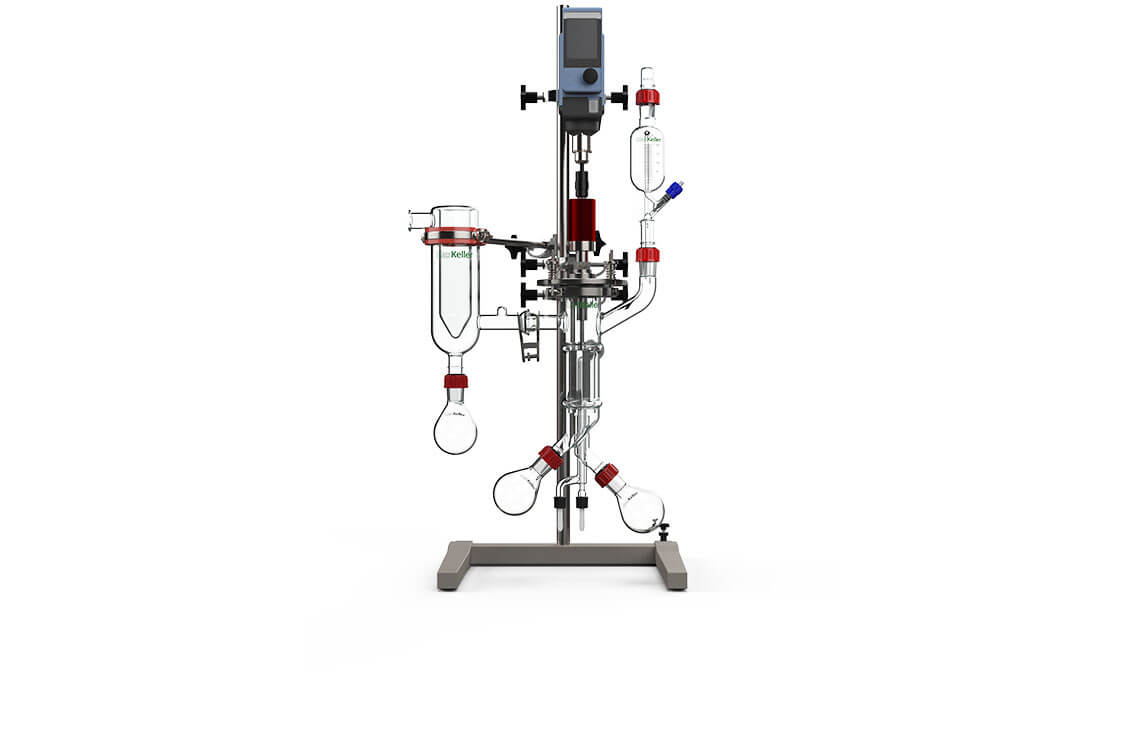

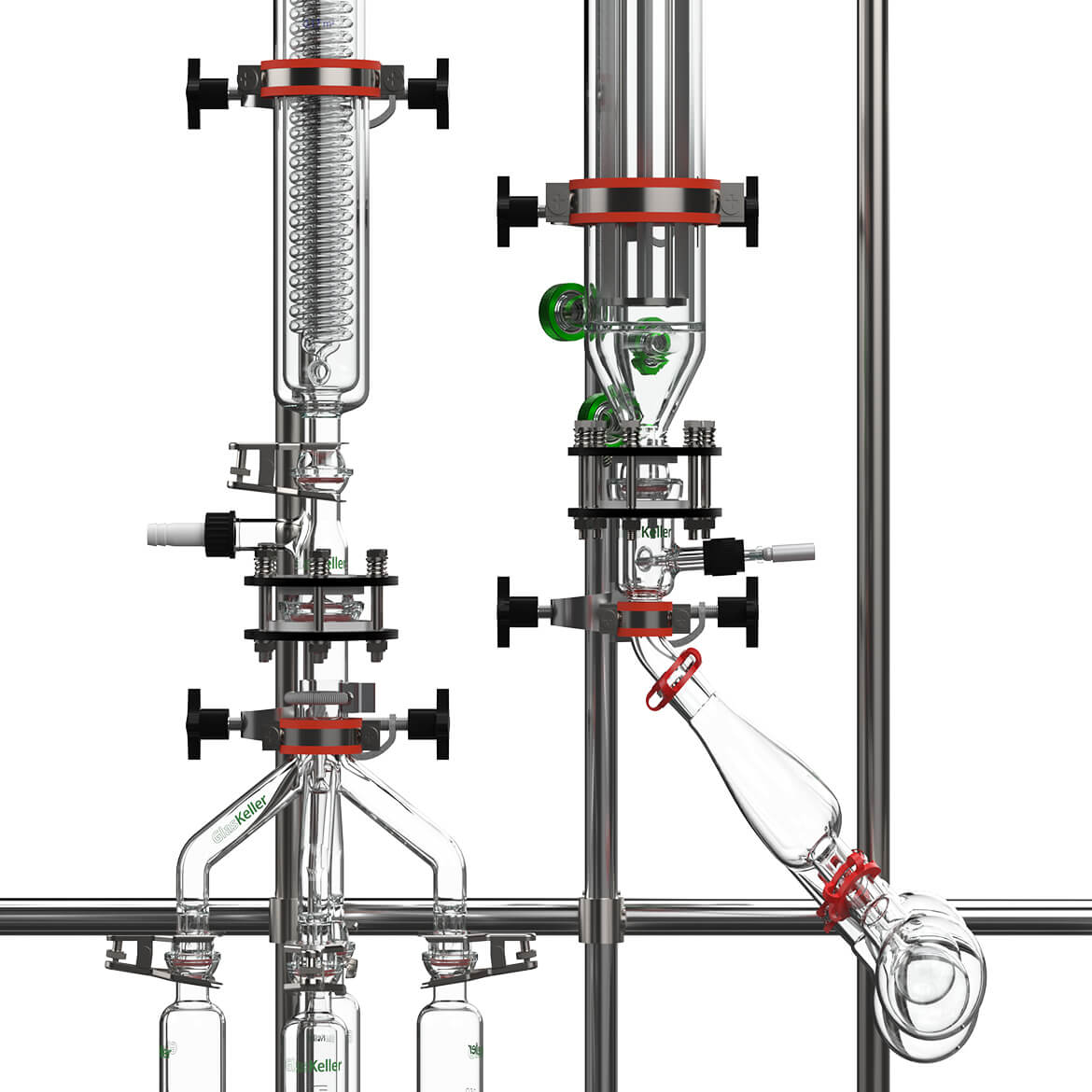

Engineered with premium materials like borosilicate glass and featuring modular components such as sump extraction and fractionating distillate drains, the evaporator is tailored to adapt to a wide range of substances. Its wiper systems—including pendulum, roller, and rigid wiper baskets—further enhance its versatility, allowing it to meet the demands of varying viscosities and complex processes with precision.

Exceptional efficiency across a wide range of substances

The thin film evaporator delivers outstanding efficiency for a broad range of substance types:

- Low viscosity: Incorporates self-cleaning roller and pendulum wipersNiedrige Viskosität: Mit selbstreinigenden Walzen- und Pendelabstreifern.

- Medium viscosity: Employs pendulum or blade wipers to ensure precise separation.

- High viscosity: Utilizes rigid wiper baskets with spring-loaded elements for effective handling.

With a PTFE compound screw conveyor enabling precise discharge of heavy boilers and short residence times minimizing product degradation, it ensures safe and reliable processing across diverse applications.

Tailored Solutions for Precision and Flexibility

GKB’s Thin Film Evaporator is expertly designed to deliver maximum precision, reliability, and flexibility, striking the ideal balance between efficiency and product protection. Its superior craftsmanship and customizable configuration make it a valuable solution for laboratories, pilot plants, and industrial production lines, even for the most demanding processes.

All our wiper types are interchangeable and are connected to the drive via a magnetic coupling. This enables optimum adaptation of the wiper type used to your applications. For high media compatibility and corrosion resistance, we offer wipers made of various materials: Metal, plastic and glass.

MESSAGE US

We are here to help

Whether you are an existing customer looking to reproduce your glassware or someone with an entirely new challenge, we deliver unbeatable product quality and excellent support from enquiry to delivery, and beyond.

Contact us to get started.