Glass Reactors

Chemical Glass reactors: unveiling the power of laboratory glassware

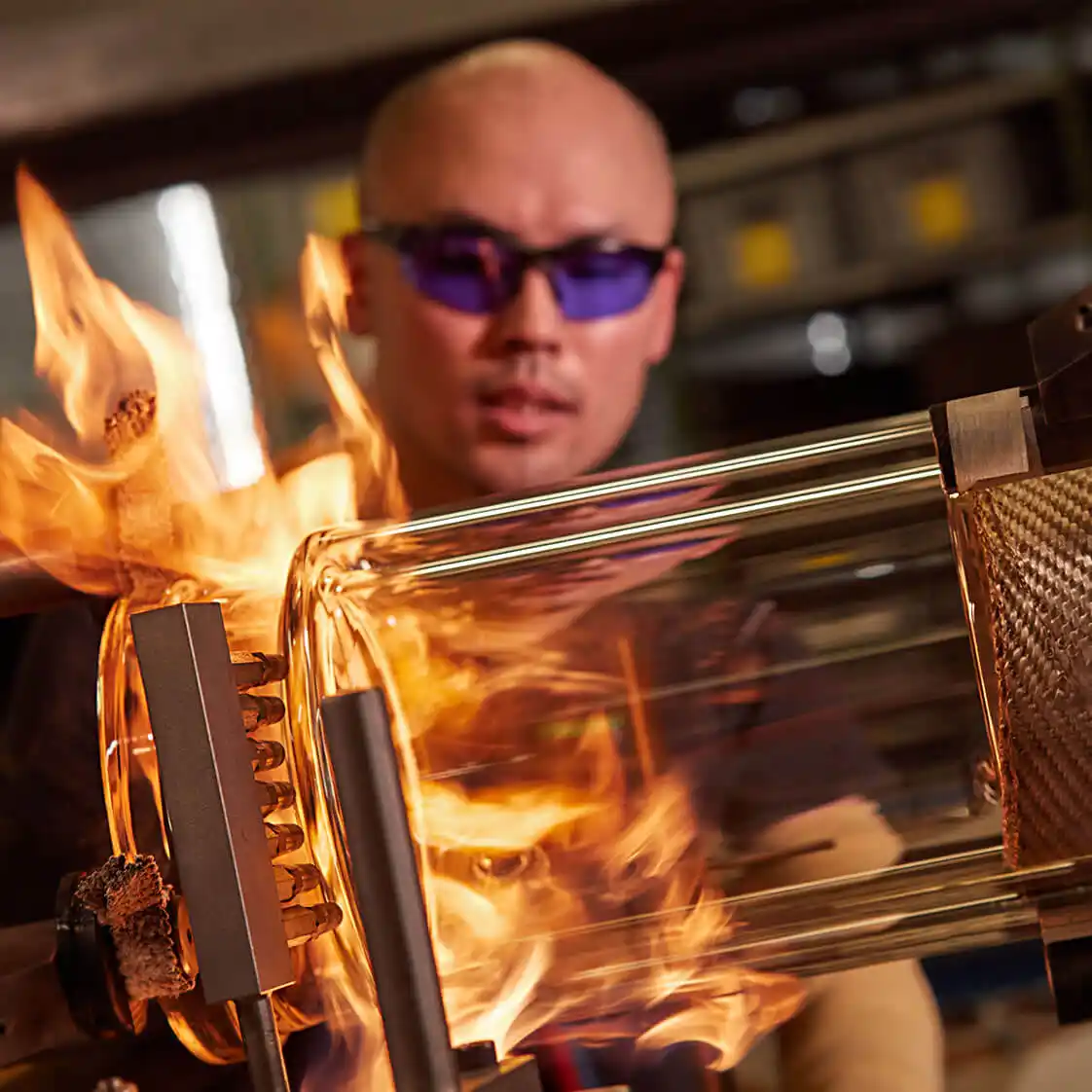

At the heart of cutting-edge laboratory processes and chemical reactions lie the unsung heroes of scientific glassware – glass reactors. These ingenious vessels, often referred to as glass reactor body stock, are indispensable tools in various industries and research settings. In this exploration of glass reactors, we delve into the fascinating world of jacketed and unjacketed glass vessel process reactors, as well as the remarkable properties of borosilicate glass in these reactors. Buckle up as we unravel the science behind these essential pieces of equipment.

Jacketed and unjacketed glass vessel process equipment

Glass reactors come in two primary types: jacketed and unjacketed. These reactors serve as the canvas upon which chemical reactions are meticulously painted, and their designs are tailored to meet specific needs. Here are some key benefits of both reactor types:

Jacketed glass reactors:

- Precise temperature control: Jacketed glass reactors allow for accurate temperature control through the circulation of heating or cooling fluids in the space between the reactor body and the jacket. This feature is crucial for reactions that are sensitive to temperature fluctuations.

- Enhanced safety: The jacket acts as a safety barrier, reducing the risk of thermal shock and protecting operators from potential burns during high-temperature experiments.

- Optimal reaction efficiency: With improved temperature control, reactions within jacketed glass reactors tend to be more efficient, producing higher yields and better-quality products.

- Versatile applications: Jacketed glass reactors are suitable for a wide range of chemical reactions, making them highly versatile and valuable in various industries.

Unjacketed glass reactors:

- Simplicity and cost-effectiveness: Unjacketed glass reactors are a cost-effective choice for processes that don’t require precise temperature control. They are easier to maintain and operate.

- High-quality borosilicate glass: Unjacketed reactors are often made of high-quality borosilicate glass, ensuring excellent chemical resistance and durability.

Borosilicate glass in reactor systems

Borosilicate glass is the star of the show when it comes to glass reactors. Its unique properties make it the go-to material for crafting reactor bodies. Here are some benefits of using borosilicate glass in reactors:

- Exceptional chemical resistance: Borosilicate glass is highly resistant to chemical corrosion, ensuring that it can withstand the harshest substances used in chemical reactions.

- Clarity and transparency: Borosilicate glass is exceptionally clear, allowing researchers to observe reactions and monitor progress without interference.

- Durability and longevity: With its remarkable strength and resistance to wear and tear, borosilicate glass ensures the longevity of glass reactor equipment.

In a world where precision, safety, and efficiency are paramount, borosilicate glass has become the cornerstone of glass reactor technology.

Exploring the advancements in glass reactors: catalysts of scientific innovation

Glass reactors, be they jacketed or unjacketed, play a pivotal role in advancing scientific research and industrial processes. With their versatility, precise temperature control, and remarkable chemical resistance, these reactors are indispensable tools for scientists and researchers across the globe. When paired with borosilicate glass, these reactors become not just vessels but trusted allies in the quest for scientific discovery and innovation

As the glass reactors market continues to evolve, it is essential to stay abreast of the latest developments in reactor systems and equipment. Whether you are working in a high-pressure laboratory setting or a large-scale production environment, the right choice of reactor type, diameter, and materials can make all the difference in the success of your chemical reactions.

So, as you venture into the dynamic world of scientific glassware, make sure to explore the wide range of glass reactor products available and choose the one that suits your specific needs. A reliable partner for scientific glassware, coupled with state-of-the-art energy recovery plants and extensive machinery for processing glass, is the key to achieving remarkable results in your experiments.

Embrace the future of scientific glassware and let glass reactors be your catalyst for groundbreaking discoveries. The glass reactor stands as a testament to the unwavering commitment to innovation and excellence in the world of scientific research and chemical processes.

Remember, in the world of glass reactors, precision, reliability, and safety are always at the forefront. When equipped with the right knowledge and equipment, you’re ready to unlock the full potential of these remarkable scientific instruments.